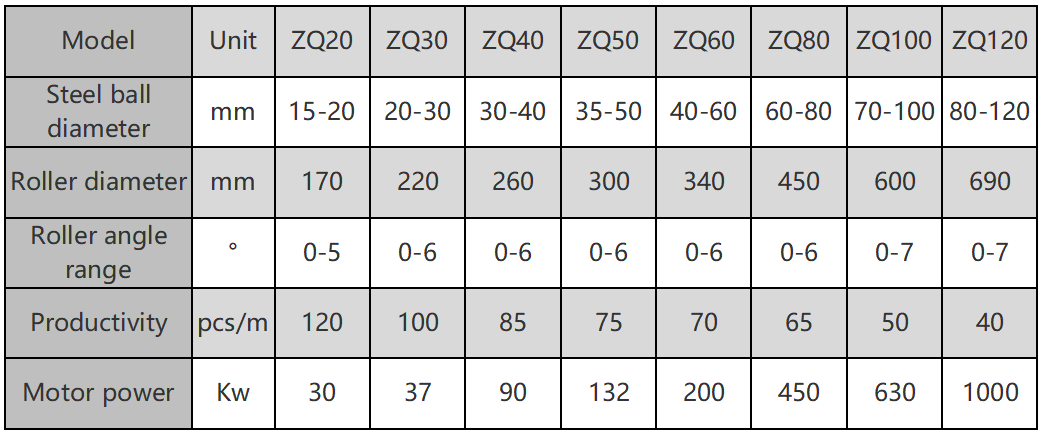

ZQ50 skew rolling production line for steel grinding ball forging process and parameters

Automatic steel ball skew rolling line without human intervention, automatic production, make sure the stability of the steel ball quality. This line production process contributes to environmental protection, saving energy but high efficiency. Steel balls have precision dimension, good roundness, high hardness, and good mechanical properties and high impact toughness, strong crushing ability, etc characteristics.

Introduction of skew rolling production line for steel grinding ball production process:

The bundles of round bar stock hanging to the “storage rack”.

Automatic feeder will be “stocker” on the round bar automatically feeding to the “intermediate frequency furnace” on the conveyor track, round bar in the conveyor track on the automatic feeding mechanism into the “electric furnace”, by adjusting the size of the power, the round steel heated to a certain temperature.

After heating, the round bar passes through the “feed guide sleeve” into the “skew rolling mill” mold, after two spiral molds, the round bar rotates forward and is continuously rolled into steel balls. From the “slide” into the “conveyor system”.

Hot rolled steel ball through the “delivery system” for transport, cooling treatment, the ball temperature uniform inside and outside, while allowing the ball temperature down to the quenching temperature, into the “quenching machine” for continuous quenching, by adjusting the “quenching machine Speed, control the temperature of the steel ball outlet, the steel ball after quenching, through the “chute” into the “material basket”, the use of tempering furnace tempering of the ball to eliminate the internal stress of the steel ball so that the ball is very high and Even hardness.

grinding steel ball rolling by skew rolling mill line, also known as abrasive wear-resistant media, is a consumable, the main purpose is to grind the material so that the material grinding finer, to achieve the use of standards, mainly used in mines, power plants, cement plants, steel mills, silica sand plant, coal chemical industry and other fields.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me