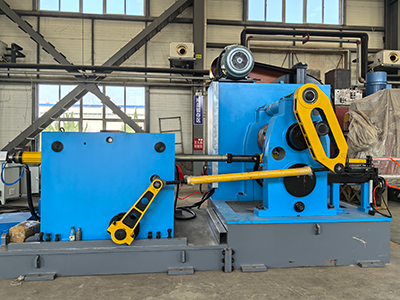

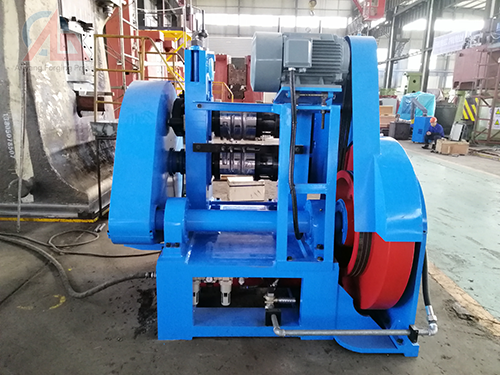

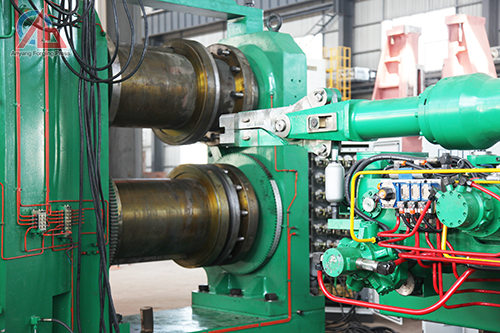

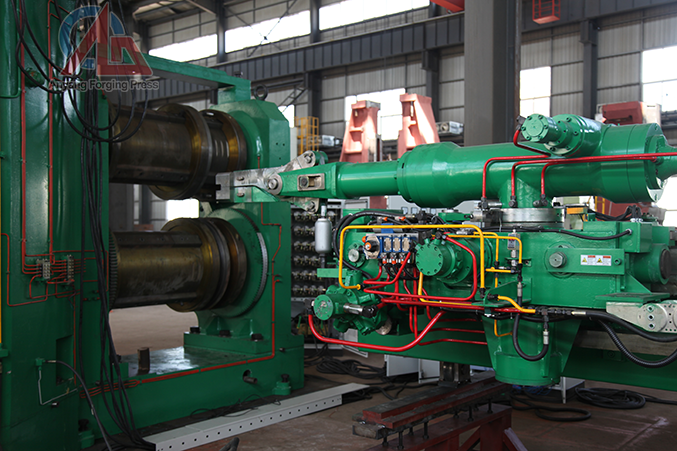

Roll forging machine is a forging equipment that continuously rolls and shapes metal billets through rotating rollers. The working principle of roll forging machine is as follows:

Blank feeding: The metal billet is fed between one or more pairs of rotating rollers.

Rolling deformation: The surface of the roller is engraved with a die groove of a specific shape, which applies pressure to the billet to cause plastic deformation.

Continuous forming: The billet passes continuously between the rollers and gradually forms the desired shape and size after multiple rolling passes.

Final forming: After multiple rolling passes, the billet reaches the final shape and the forging process is completed.

Roll Forging Machine Application

Automobile Manufacturing

Engine Parts: such as connecting rods, crankshafts, camshafts, etc.

Transmission System Parts: such as gears, shaft parts, etc.

Body Structures: such as door hinges, chassis parts, etc.

Aerospace

High-strength structural parts: such as aircraft landing gear, engine blades, etc.

Precision parts: such as turbine discs, shaft parts, etc.

Machinery Manufacturing

General Parts: such as bearings, gears, shaft parts, etc.

Tool Manufacturing: Preforming of tools such as hammers and wrenches.

Energy Equipment

Oil and gas pipelines: such as pipe fittings, flanges, etc.

Wind power equipment: such as fan shafts, gearbox parts, etc.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.