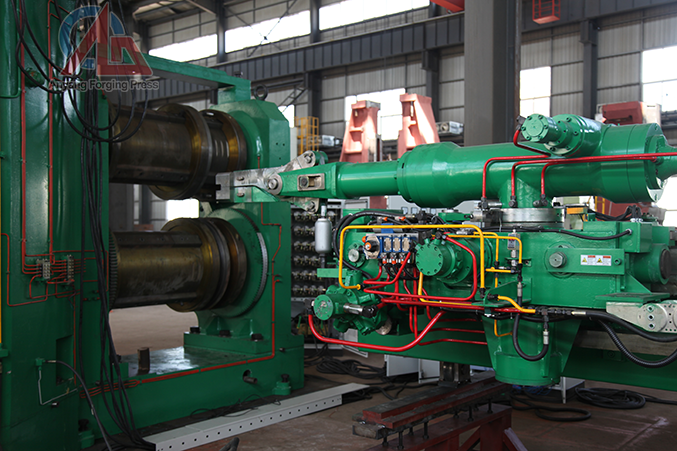

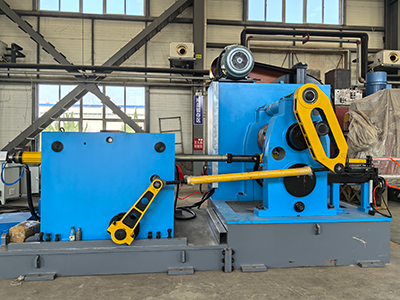

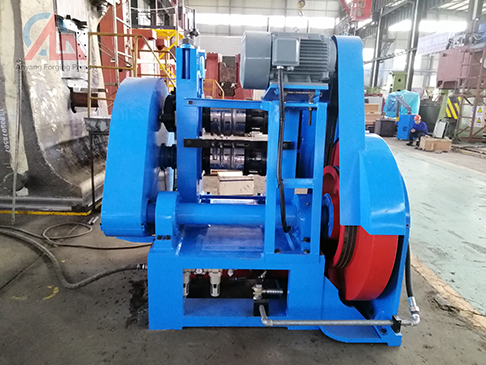

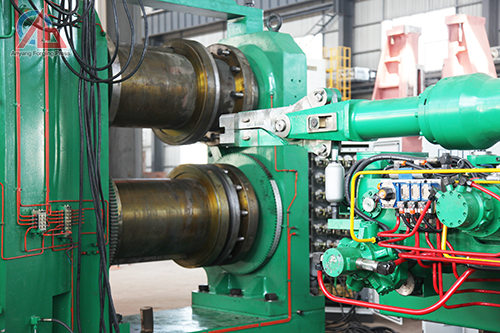

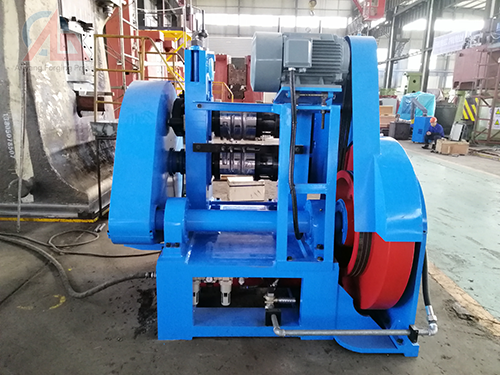

The roll forging machine is a forging device that uses rotating rollers to plastically form metal materials. It is usually used for processing long shafts, plates or complex-shaped workpieces, and is widely used in the automotive, aerospace, machinery manufacturing and other industries.

Features of Roll forging machine

Multi-pass processing: Through multiple passes of rolling, complex shapes are gradually formed.

High degree of automation: equipped with automatic feeding, positioning and control systems to reduce manual intervention.

Strong adaptability: can process a variety of metal materials, such as steel, aluminum, copper, etc.

Low noise and low vibration: compared with traditional forging hammers, the working environment is more friendly.

High-precision forming: high forming accuracy of workpieces, reducing the amount of subsequent processing.

Advantages of Roll forging machine

Efficient production: continuous processing method significantly improves production efficiency.

Material saving: high material utilization, reduced waste and reduced costs.

Energy saving and environmental protection: low energy consumption, in line with green manufacturing requirements.

Wide application: suitable for multiple industries such as automobiles, aerospace, and machinery manufacturing.

Felicia

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.