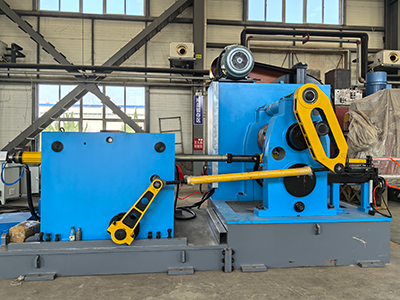

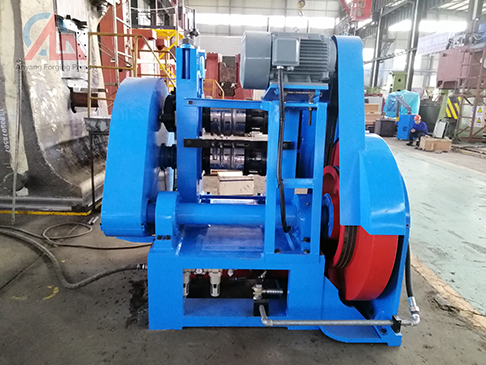

Roll forging machine is a kind of equipment used for metal processing, which mainly uses the rotation and pressure of rollers to forge metal materials. The following are the characteristics and applications of roll forging machine:

Roll forging machine features:

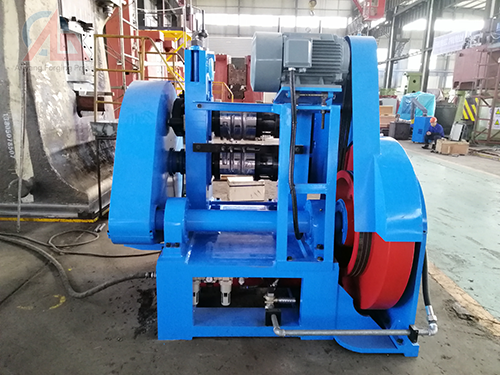

High efficiency: Roll forging machine has high production efficiency, can be operated continuously, and is suitable for mass production.

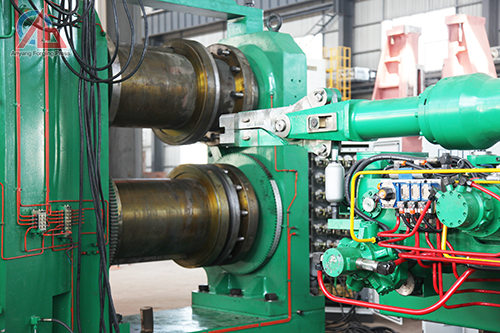

Strong adaptability: It can process a variety of metal materials, including steel, aluminum, copper, etc., and adapt to the manufacture of products of different shapes and sizes.

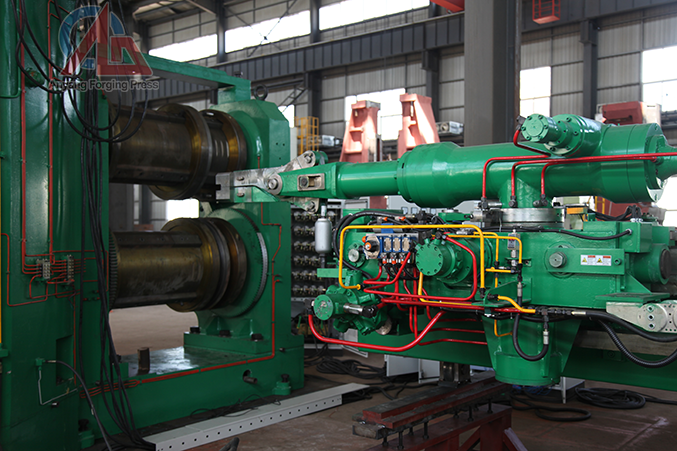

High material utilization rate: Due to the plastic deformation during roll forging, the material utilization rate is high, and compared with some traditional forging methods, it has less waste.

Excellent finished product quality: Roll forging can improve the internal structure of metal, improve the mechanical properties of products, reduce defects, and increase the strength and toughness of products.

High degree of automation: Modern roll forging machines are generally equipped with automatic control systems, which can achieve precise control and improve processing accuracy.

Long die life: Due to the working mode of roll forging, the die wear is relatively small and the service life is long.

Roll Forging Machine Application

Applicable to many industries such as construction, machinery, manufacturing, etc., it is the best choice for users in various industries.

Choose our wedge iron machine to improve your work efficiency and ensure the success of every project. Contact us now to learn more and create a brilliant future together with us!

Felicia

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me