Hydraulic Open Die Forging Press is a common hydraulic forming equipment, widely used in metal forming, casting, plastic pressing and other industries.

Y13 series Hydraulic Open Die Forging Press structural features and advantages include:

Three-beam four-column structure: This model consists of three beams (upper beam and lower beam) and four columns, with good stability and load-bearing capacity. The upper and lower beams can achieve synchronous movement to ensure that the pressure applied to the workpiece is evenly distributed.

Strong load-bearing capacity: The three-beam four-column structure can withstand greater pressure, making the hydraulic press suitable for high-intensity work such as heavy forging and stamping.

Positioning accuracy: Through precise guidance and hydraulic control systems, high-precision pressure control and position control can be achieved to improve the forming accuracy of the workpiece.

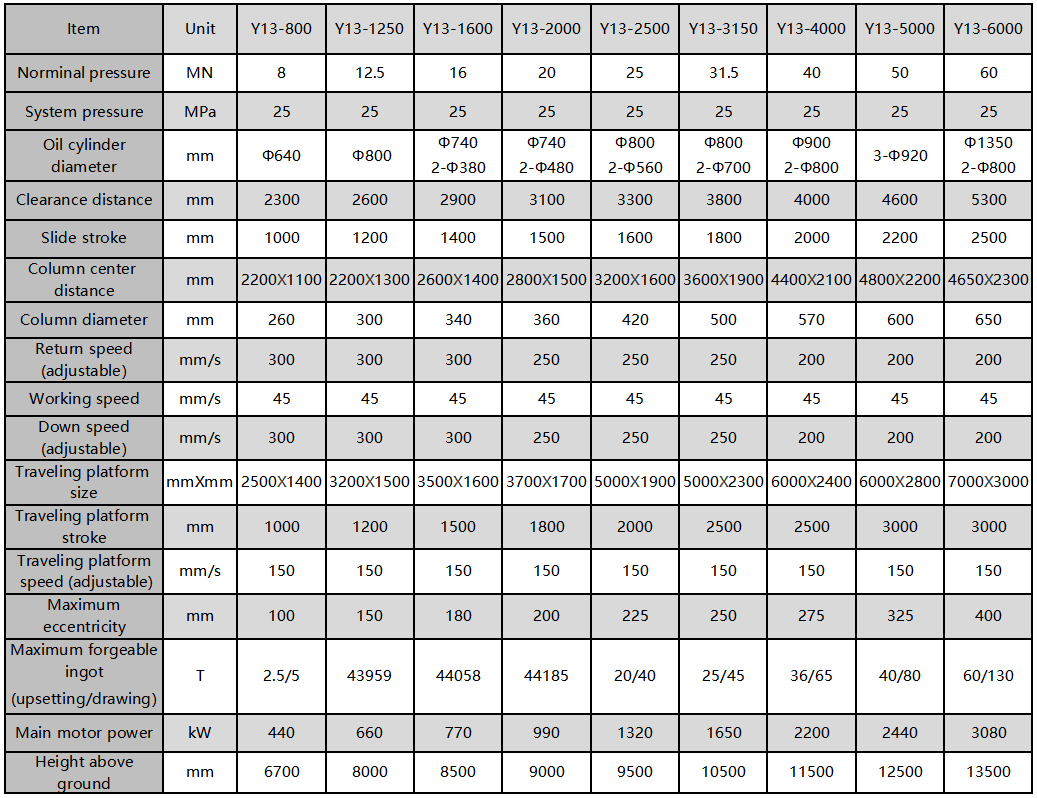

Pressure and stroke adjustment: The operator can easily adjust the pressure size and working stroke according to the process requirements, which improves flexibility.

Wide range of applications: It can be used for a variety of processes, such as stamping, bending, forming, cutting, etc., suitable for the processing of different materials such as plastics, metals, rubber, etc.

Protection device: It is usually equipped with a variety of safety devices, such as pressure overload protection, mechanical limit protection, etc., to ensure the safety of equipment and operators.

Easy to maintain: The structure is simple, and repair and maintenance are relatively easy, which reduces the maintenance cost.

In general, the Y13 series Hydraulic Open Die Forging Press is widely favored by various industries for its superior performance and flexible application, and is an indispensable and important equipment in modern manufacturing.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.