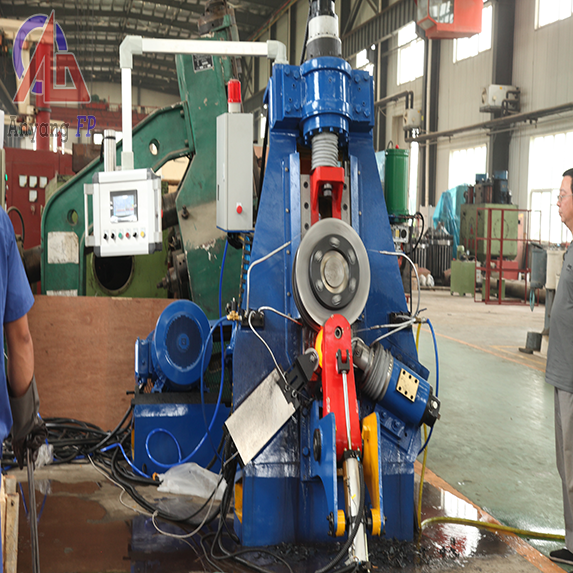

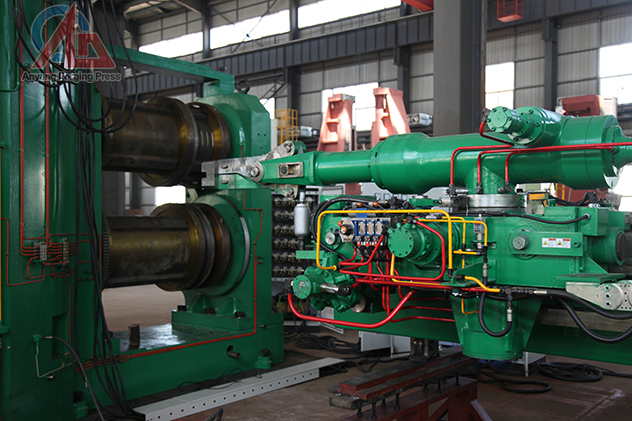

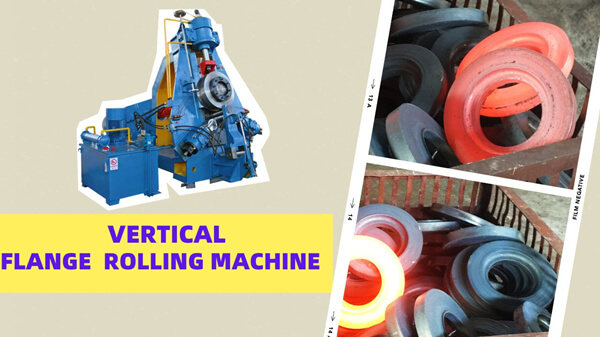

Vertical Ring Rolling Machine Forging Rings Process Flow and Application

The process of forging rings with a ring rolling machine involves gradually deforming metal materials into ring-shaped parts through the action of rolling wheels. This process has significant technical and economic value and is applicable to multiple industries.

The process flow of forging rings

Material selection: According to the application requirements of the product, select suitable metal materials (such as carbon steel, alloy steel, etc.).

Heating: Heating the material to the appropriate forging temperature to improve the plasticity of the material.

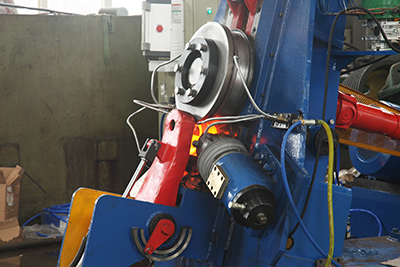

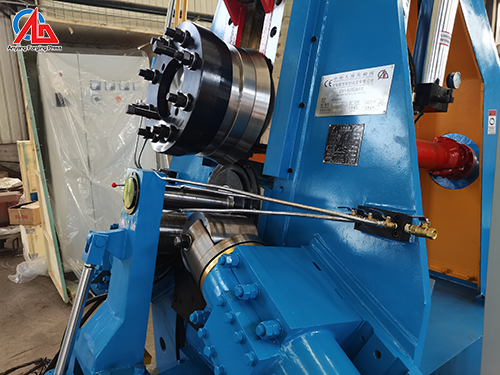

Clamping and positioning: Position and clamp the heated material into the ring rolling machine.

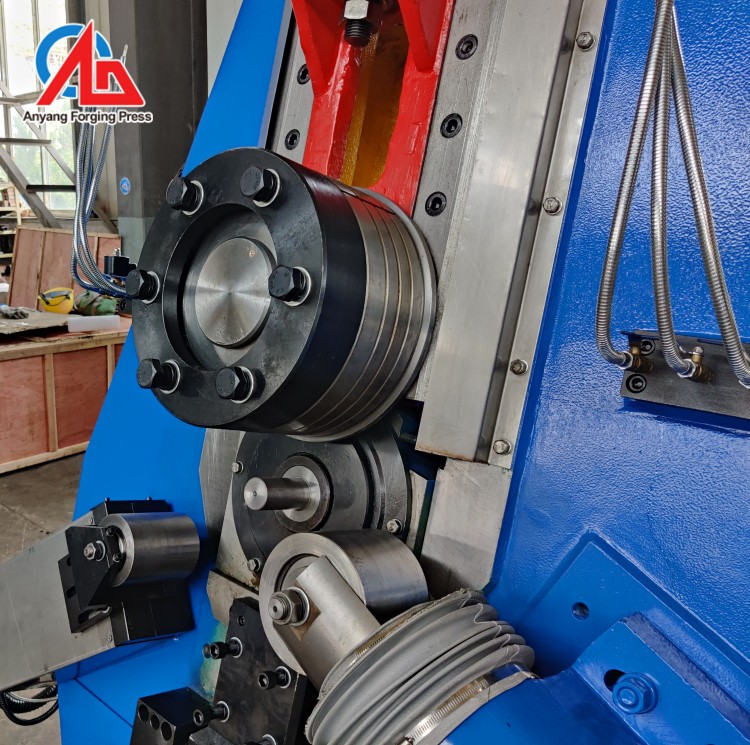

Rolling forming: start the ring rolling machine for forging, and gradually roll to form a ring.

Cooling: After forging is completed, cool naturally or use water cooling to reduce the temperature.

Post-processing: including descaling, heat treatment, mechanical processing, etc. to improve performance and accuracy.

Quality inspection: Inspect finished rings to ensure compliance with size and performance requirements.

Rings forged by ring rolling machines are widely used in the following fields:

Aerospace: used to manufacture aerospace engine components, hubs, sealing rings, etc.

Automobile industry: Produces important components such as drive shafts and gears for automobiles.

Heavy machinery: used to manufacture key ring parts for cranes and small machinery.

Oil and Gas: Used in the production of valves, flanges and other pressure vessel components.

felicia@anyanghammer.com

WhatsA.pp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.