The rapid hydraulic riveting machine is widely used in industries with a riveting structure such as automobiles, rolling stock, aviation, and mine cars.

Compared with pneumatic riveting, hydraulic riveting has the following advantages:

1. No noise;

2. Low labor intensity;

3. Fast riveting speed;

4. High riveting force, both cold riveting and hot riveting are acceptable;

5. The force of the rivet is uniform, the riveting quality is good, and the local deformation of the frame can be corrected.

Therefore, most countries have generally adopted hydraulic riveting machines.

[1] Composition and classification of rapid hydraulic riveting machine:

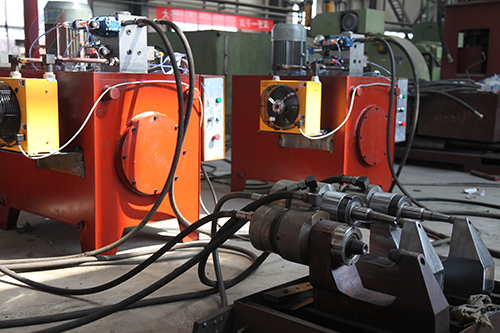

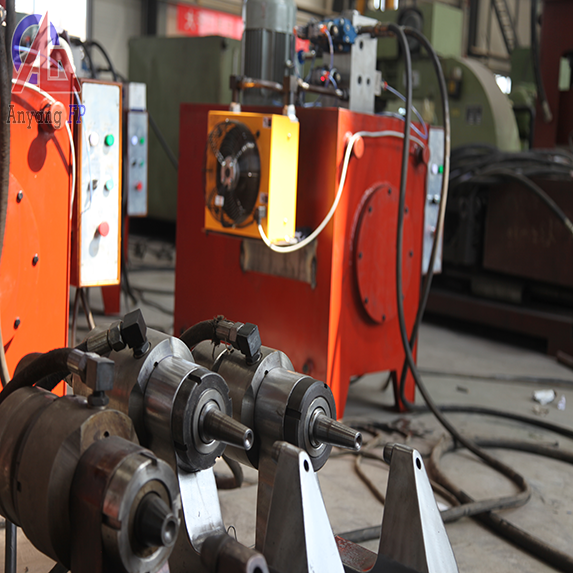

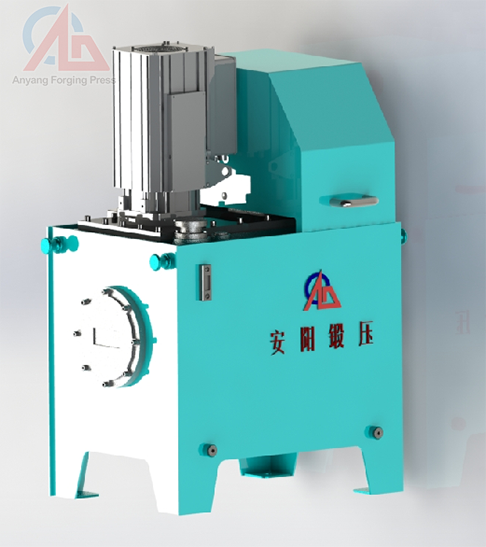

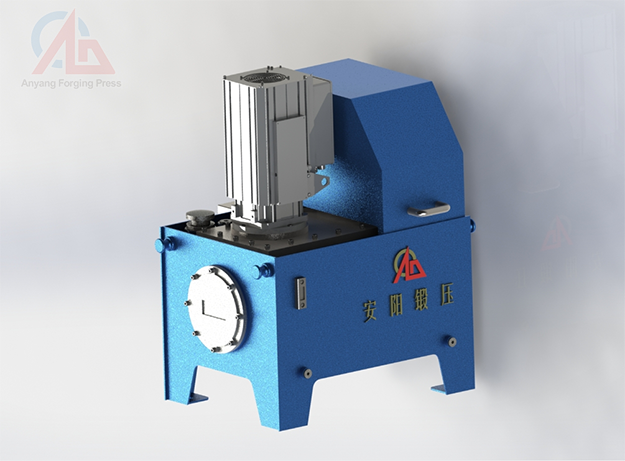

A hydraulic riveting machine is mainly composed of a hydraulic station, riveting pliers, spreader, balancer, trolley, slide rail, and high-pressure hose.

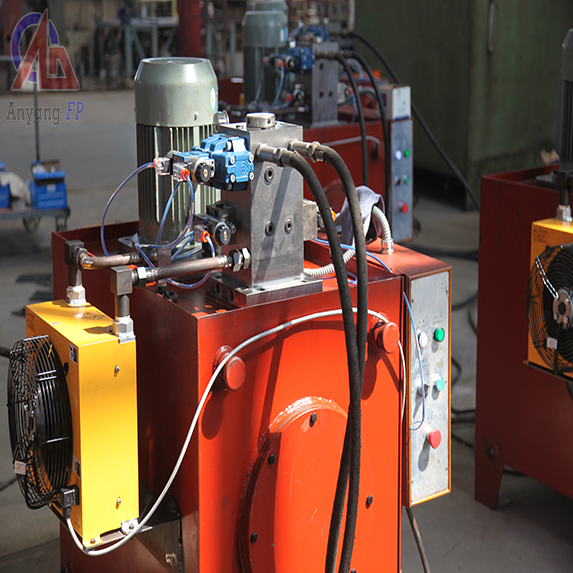

The hydraulic station is the power and control unit of the fast hydraulic riveting machine, and it is also a key part of the performance of the riveting machine.

The hydraulic station is mainly composed of an oil tank, valve group, booster cylinder, oil pump motor group, and electrical system.

According to the characteristics of cold and hot riveting and the structure of the hydraulic valve, the hydraulic station is divided into two series: cartridge valve series and plate series.

[1] Composition and classification of riveting pliers of rapid hydraulic riveting machine

The main components of riveting pliers include the riveting plier’s oil cylinders, riveting pliers body, dynamic riveting die, static riveting die and handle buttons, etc. The riveting pliers can be divided into suspension type and horizontal type, as well as trolley type and fixed type.

***************************************************************************************************************************************************************

If you are interested in it, pls contact me.

Felicia

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870