The Scope and Characteristics of the Screw Press Forging

The Scope and Characteristics of the Screw Press Forging

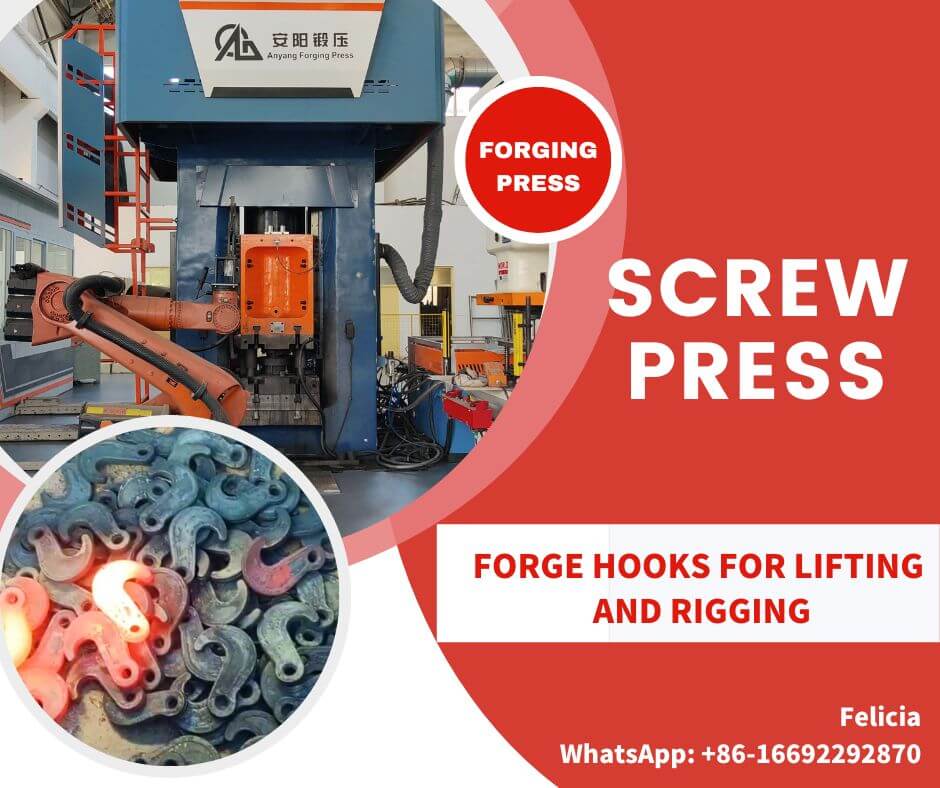

Electric screw presses are suitable for forging various die forgings, such as turbine blades and special bolts in the aviation industry, engine valves, differential gears, connecting rods, claw poles in the automotive industry, and surgical forceps in the medical industry. With the development of science and technology, various industries have higher and higher requirements for the precision of die forgings. Compared with traditional die forging equipment, an electric screw press is ideal equipment for producing precision die forgings.

The Scope and Characteristics of the Screw Press Forging

- Electric screw presses are suitable for forging various die forgings, such as turbine blades and special bolts in the aviation industry, engine valves, differential gears, connecting rods, claw poles in the automotive industry, and surgical forceps in the medical industry. With the development of science and technology, various industries have higher and higher requirements for the precision of die forgings. Compared with traditional die forging equipment, an electric screw press is ideal equipment for producing precision die forgings.

- The electric screw press is not only forging equipment with strong process applicability but also environmentally friendly and energy-saving precision forming equipment. It has a simple structure, small size, convenient operation, high transmission efficiency, and saves 50% of electricity than friction presses or more, the failure rate is low, and the cost performance is high.

The Advantages of the intelligent Electric Screw Press of Anyang Forging Press

The intelligent Electric Screw Press of Anyang Forging Press is a new generation of an Electric Screw Press with more intelligent control systems, better stiffness and strength, and better forging accuracy. The specific advantages are as follows:

Intelligent module

1. Collect device information online

It can collect equipment information such as motor temperature, slider position, slider speed, and actual strike energy online, monitor and record the operation of the equipment, and perform online monitoring and offline statistical analysis on the status of the equipment.

2. Warning parameter setting

The early warning parameters are mainly for recording the service life cycle of consumables and wearing parts on the equipment, and periodically alarming. The main data is the data reminder according to the equipment inspection table and maintenance cycle table.

3. Device documentation query

Mainly include the user manual, electrical schematic diagram, maintenance manual, and other documents of the built-in equipment on the equipment display screen: common fault judgment and maintenance instructions, lubrication instructions, inspection table, after-sales maintenance contact information, etc.

4. OEE data

Through the smart meter, the power usage of the equipment during the entire operation process is counted. The smart meter and the PLC jointly make statistics on the operation time, unexpected downtime, and debugging time. utilization. Combined with the original formula module of the equipment, the actual output of the equipment is statistically analyzed.

Control system

The imported ABB frequency converter controls the AC asynchronous motor, which is more suitable for precise control conditions. The motor has low power density and high energy utilization. The energy control precision is high.

Detection and control system

The linear guide is used to detect the position and speed of the slider at any time, which can realize closed-loop control. This machine has a slider stroke measurement system, a forging thickness measurement system, an energy measurement system and a final forging temperature measurement system (optional).

Overall body + pull bar

The series of electric screw presses developed by Anyang Forging and Pressing Company have all optimized the design of the fuselage. In the interior of the fuselage, especially at the guide rail force, the usually elongated rib plates are added, which greatly enhances the vertical rigidity and lateral rigidity. The 1000 tons ( Presses above 1000 tons) are additionally equipped with prestressed tie bars. Through the design, the extra energy is borne by the pull bar, which greatly improves the reliability of the fuselage and the whole machine. The 2500-ton super-large electric screw press adopts the split technical structure.

Transmission mechanism

The electric screw press developed by Anyang Forging Company has two structures. One is the asynchronous motor controlled by the frequency converter, and the large gear (combined with the flywheel) is driven by the pinion. The friction slip mechanism is used between the pinion and the motor to protect the motor from overloading. Another structure is the direct drive screw press, which has higher efficiency and better strike energy accuracy due to the elimination of the gear transmission system.

Slide guide

Long slider, long guide rail, high precision, and easy adjustment.

Intelligent automatic production line

Connect forging robots, automatic inkjets, and other automation devices to form an intelligent automatic forging production line with intelligent electric screw press as the core equipment.

If you are interested in it, pls contact me.

Felicia

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870