Electric screw press and friction press are two common forging equipment, which have significant differences in working principle, performance characteristics and application scenarios. The following is the main comparison between the two:

Working principle

Electric screw press:

It is driven by an electric motor, and the rotary motion is converted into linear motion through the spiral transmission of the screw and nut to achieve striking. The striking energy is directly controlled by the motor, and the energy transfer efficiency is high.

Friction press:

It is driven by a friction wheel, and the friction between the friction wheel and the flywheel drives the screw to rotate to achieve striking. The striking energy is determined by the contact time of the friction wheel controlled by the operator through the handle, and the energy transfer efficiency is low.

Energy control

Electric screw press:

The striking energy can be precisely controlled, and stepless adjustment can be achieved by adjusting the speed and current of the motor. Suitable for high-precision forging, good energy repeatability.

Friction press:

The striking energy depends on the operator’s experience, and the control accuracy is low. The energy repeatability is poor, not suitable for high-precision forging.

Efficiency and energy consumption

Electric screw press:

High energy utilization rate and good energy saving effect. High striking frequency and high production efficiency.

Friction press:

Energy utilization is low and energy consumption is high. The striking frequency is low and the production efficiency is relatively low.

Degree of automation

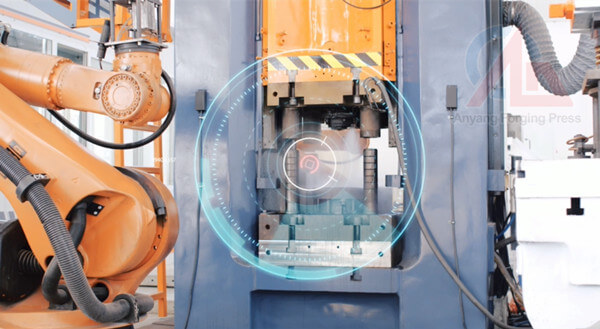

Electric screw press:

High degree of automation, can be equipped with PLC control system to realize automatic operation. Suitable for modern production lines and reduce manual intervention.

Friction press:

Relying on manual operation, low degree of automation. Suitable for small batch or traditional production mode.

Application scenario

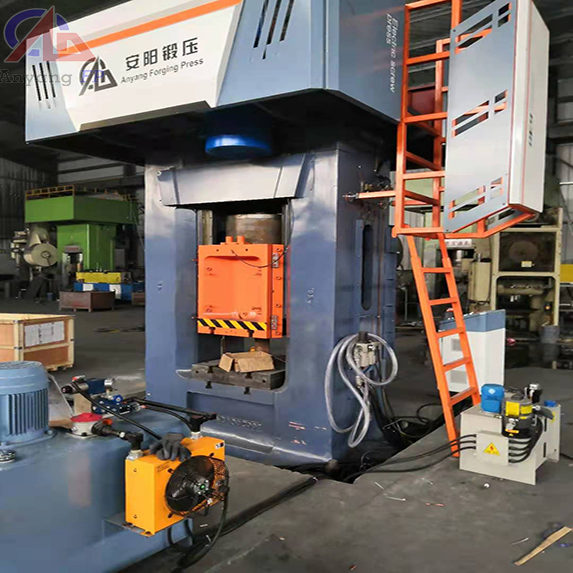

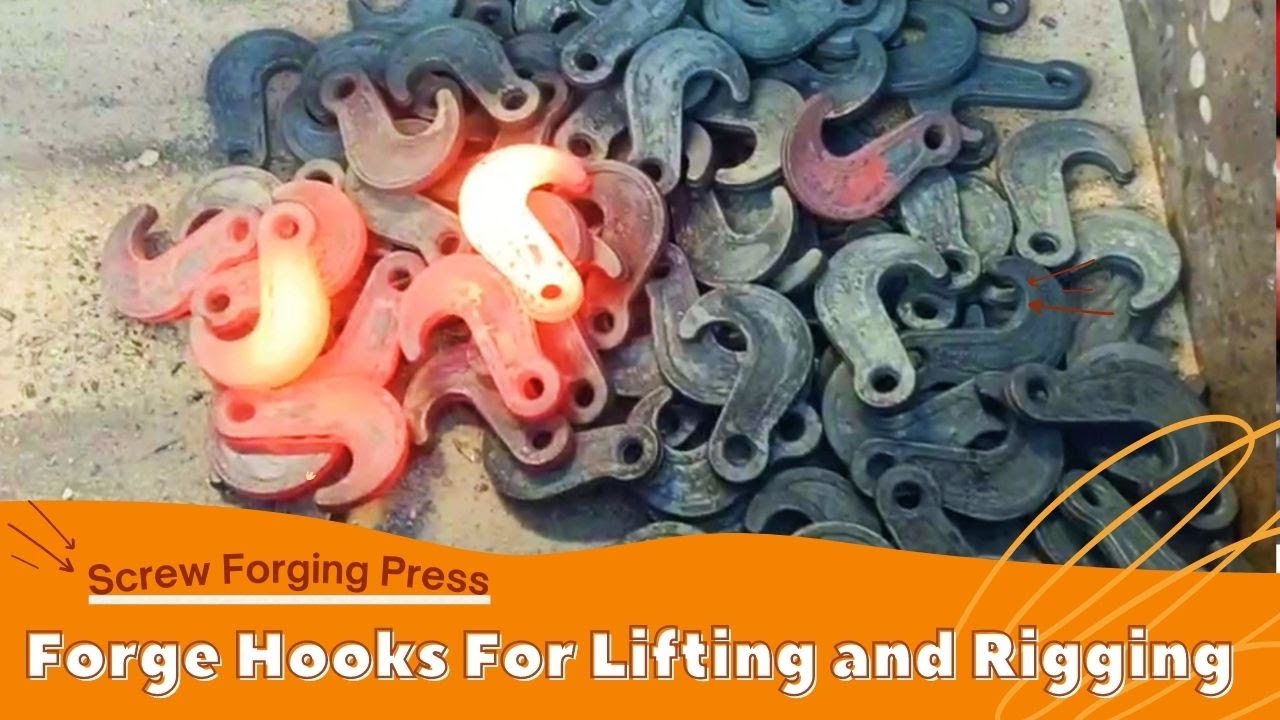

Electric screw press:

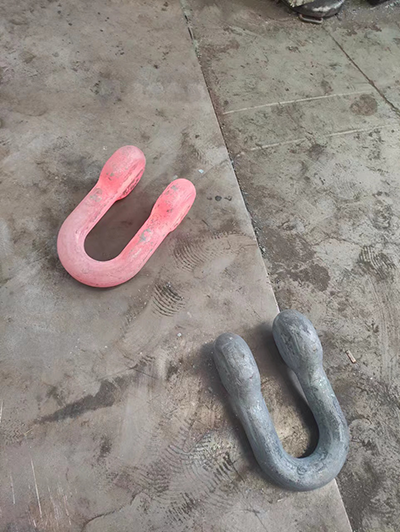

Suitable for high-precision and large-scale production, such as precision forging, die forging, etc. Widely used in automobile, aerospace, electronics and other industries.

Friction press:

Suitable for small batch and low-precision production, such as simple forging, stamping, etc. Mostly used in traditional manufacturing or small processing plants.

According to production needs and budget, users can choose the appropriate type of equipment. For modern and high-demand forging production, electric screw press is a better choice; while for traditional or small-scale production, friction press still has certain application value.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.