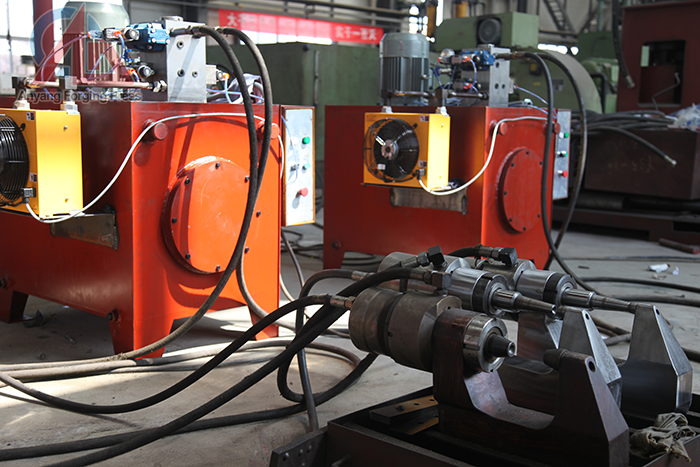

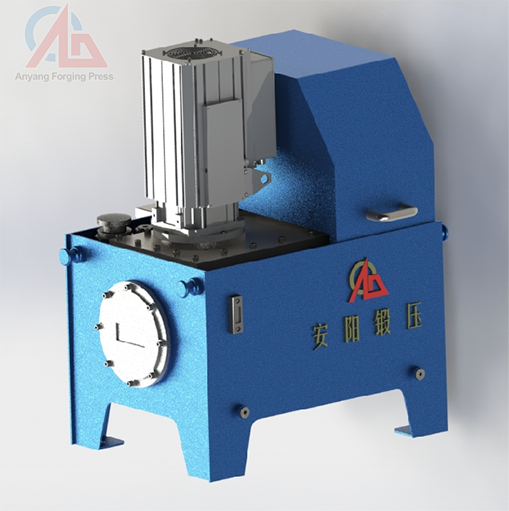

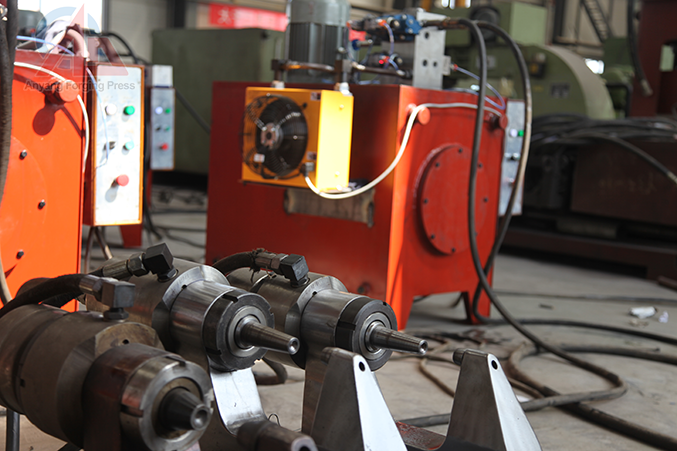

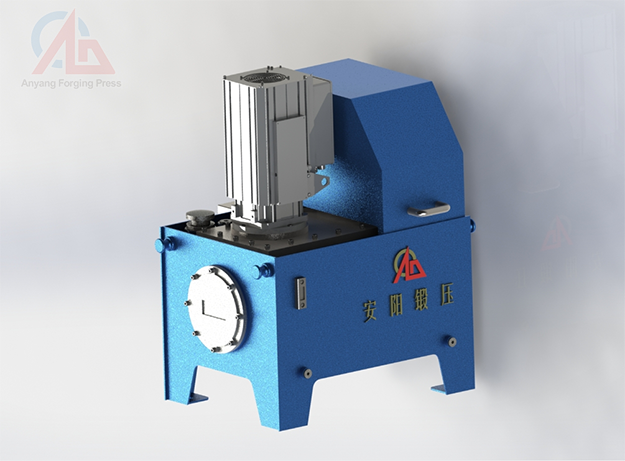

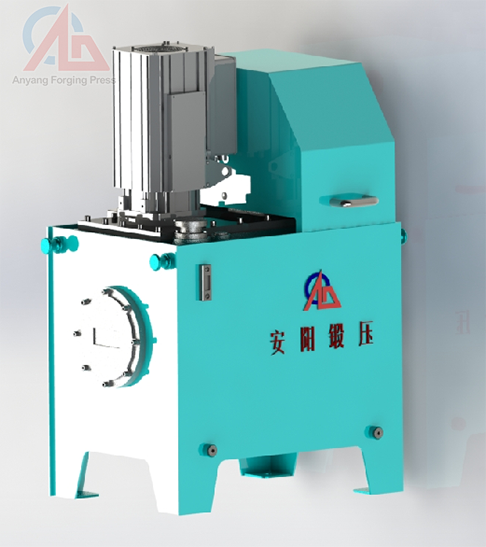

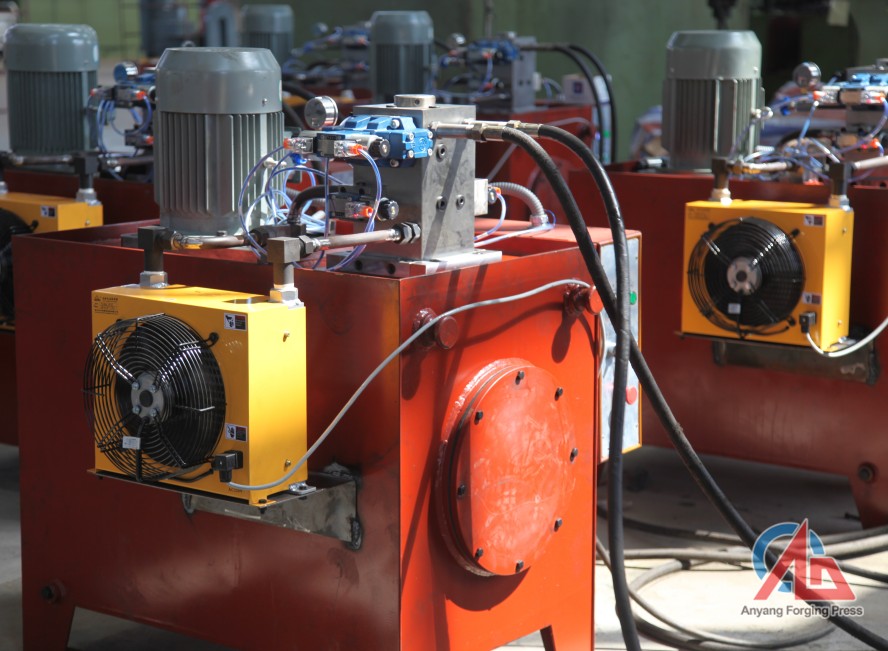

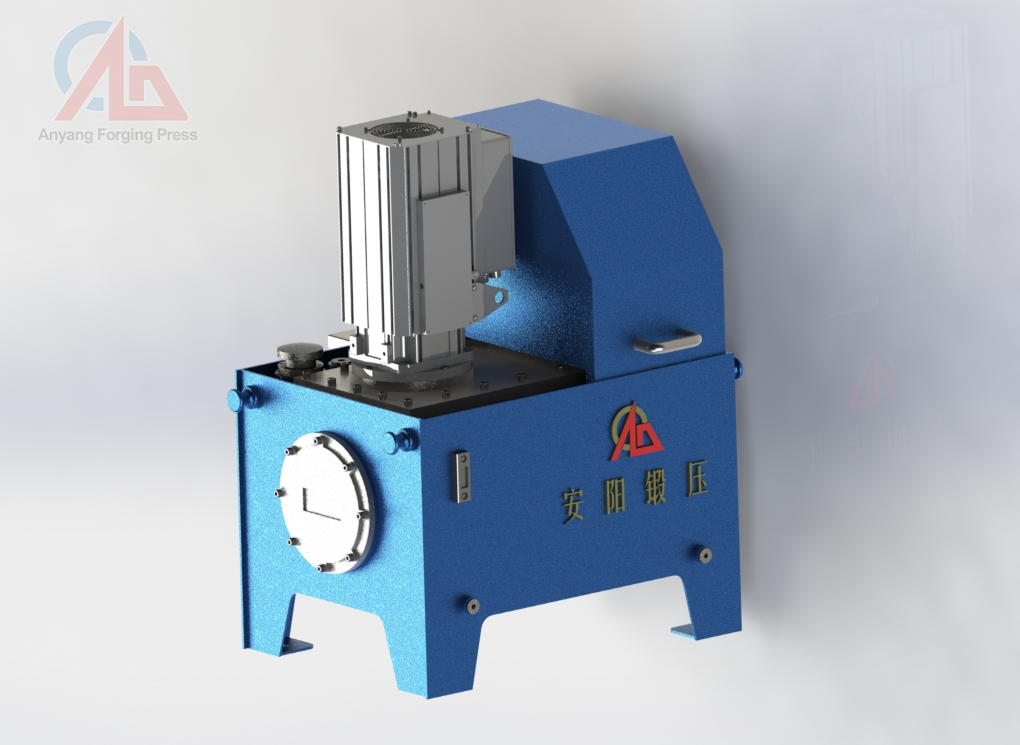

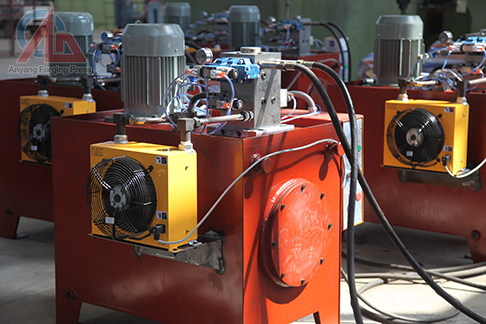

The suspended hydraulic riveting machine is a kind of equipment suitable for riveting and connecting metal parts. It is widely used in manufacturing, engineering machinery, aerospace, automobile and other fields. The following are some main technical parameters and application introductions of the suspended hydraulic riveting machine.

Main technical parameters of the suspended hydraulic riveting machine

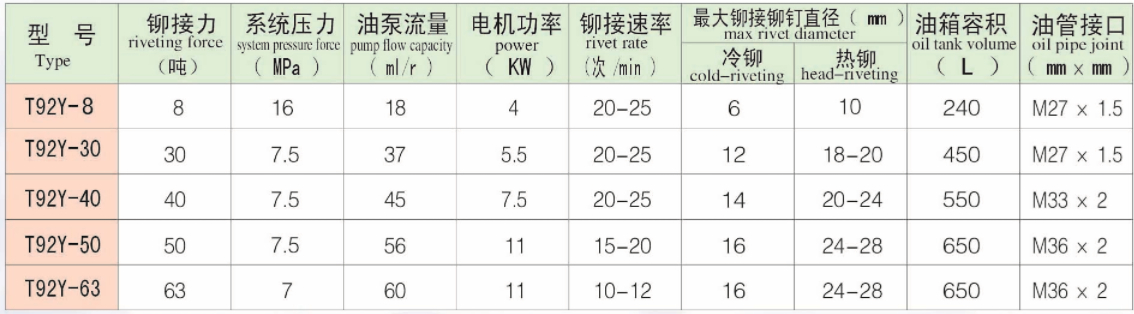

Maximum riveting force: usually between tens of tons and hundreds of tons, which varies according to different models.

Maximum riveting diameter: generally a few millimeters to a few centimeters, and the appropriate tool can be selected according to specific work needs.

Workbench size: The size of the workbench is usually designed to facilitate the placement of workpieces that need to be riveted, and the size can be customized.

Control method: often equipped with manual and automatic control systems, and some models also support CNC systems to achieve precise riveting operations.

Application of suspended hydraulic riveting machine

Automotive manufacturing: used for riveting of car bodies, chassis and other structural parts.

Aerospace: used for riveting of complex structures such as aircraft fuselages, wings, engines, etc.

Engineering machinery: used for riveting of large engineering machinery parts such as excavators and cranes.

Shipbuilding: plays an important role in the connection of hull and deck structures.

The suspended hydraulic riveting machine has become a key equipment in many heavy industrial fields due to its high efficiency, precision and strong adaptability.

Felicia

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.