Skew rolling machine for grinding balls forging process

Raw material preparation: Select suitable steel as raw material, usually high-strength alloy steel or forged steel.

Heating: Heat the raw material to an appropriate temperature for subsequent forging processing. The heating temperature is usually between 1100℃-1250℃.

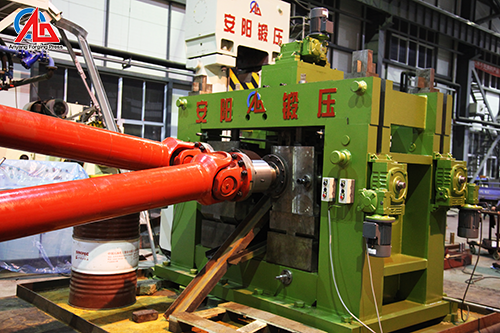

Forging: Forge the heated material using a skew rolling machine to form it into an ideal shape through pressing and deformation. The skew rolling method can improve the density and uniformity of the material.

Heat treatment: Forged workpieces usually need to be heat treated (such as normalizing, quenching and tempering) to improve their mechanical properties and wear resistance.

Inspection: Inspect the finished product in terms of size, hardness and surface defects to ensure that it meets the use standards.

In terms of price, the cost of skew rolling machine for grinding balls will be affected by many factors, including the type and price of raw materials, investment in forging equipment, labor cost, heat treatment process and market demand.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.