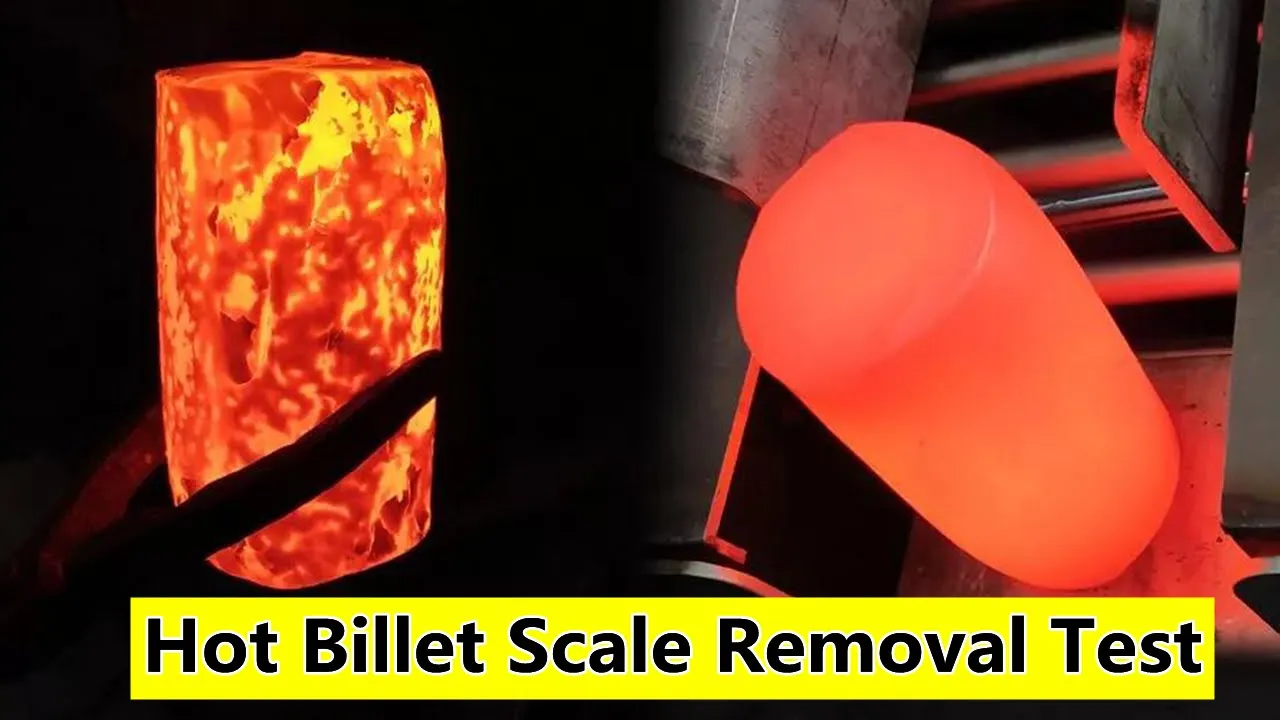

In the forging production process, the metal blank need to be heated to high temperature, steel react with oxygen on the billet surface, which will generate a layer of scale.If it can’t be removed before forging production, some pits may occur on the surface, which not only affect the appearance quality, but also reduce local strength, if these pits appearing on machined parts of forging, will also reduce machining allowances, and have the risk of processing scrap.

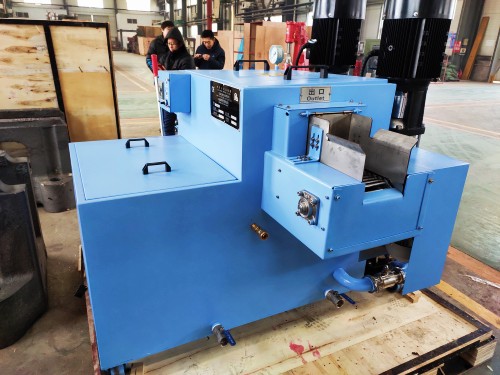

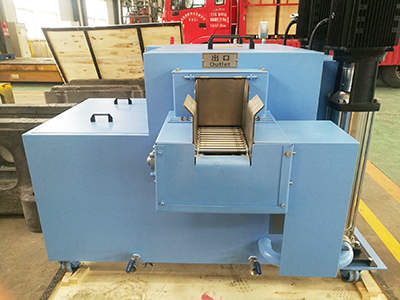

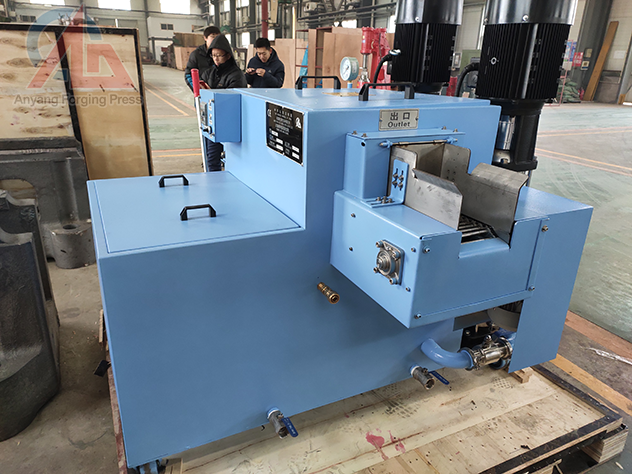

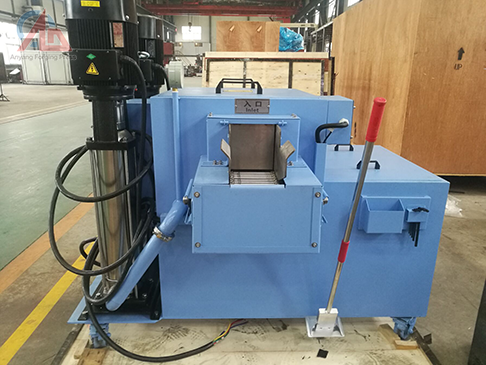

Rust removal method of metal descaling machine:

(1) Knocking on the forging equipment, using metal deformation to remove the oxide scale, which can reduce the production cycle;

(2) Rust removal device, removes the oxide scale generated by the billet during the heating process before forging production, using position adjustment bolts and scraper replacement, it can be widely adapted to billets of various shapes and sizes. In addition, by replacing the preset torsion spring, billets of different materials can be removed.