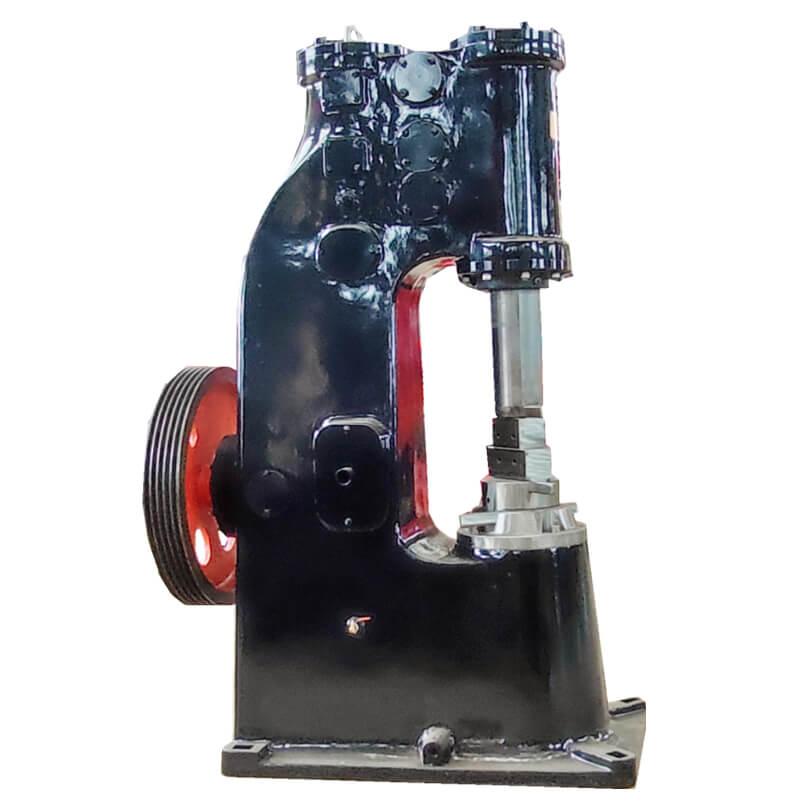

power hammers / Knife Maker Air Hammers / Small Air Hammer Manufacturers in India

Items to check before using the blacksmith air hammer:

1. Check that the vibration parts are not loose, the hammer head is free of cracks, and the wedge of the hammer head and anvil should be tight. The air hammer cylinder should be well lubricated, adjust the oil intake, and fill the cylinder oil as required.

2. Shake the lubricator for 20-30 turns in advance to supply oil and lubricate in advance.

3. The oxide scale on the surface of the anvil and the hammer should be removed.

4. Before working in winter, the hammer, anvil and forging die should be preheated to above 60℃.

5. The geometric dimensions of the forgings should be checked, and forgings that exceed the hammering capacity of the forging hammer are strictly prohibited.

Luking

Luking@anyanghammer.com

WhatsApp/WeChat: +86-16692292860

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me