- Home

- Open Die Forging Machine

- Closed Die Forging Machine

- Steel Ball Machine

- Blacksmith Forging Equipment

- Other Machine

- Automatic Roll Forging Machine

- Automatic Spray Graphite Machine

- Billet Cutting Machine

- CNC Forging Manipulator

- CNC Ring Rolling Machine (D53K-Horizontal)

- Frame Type Forging Manipulator

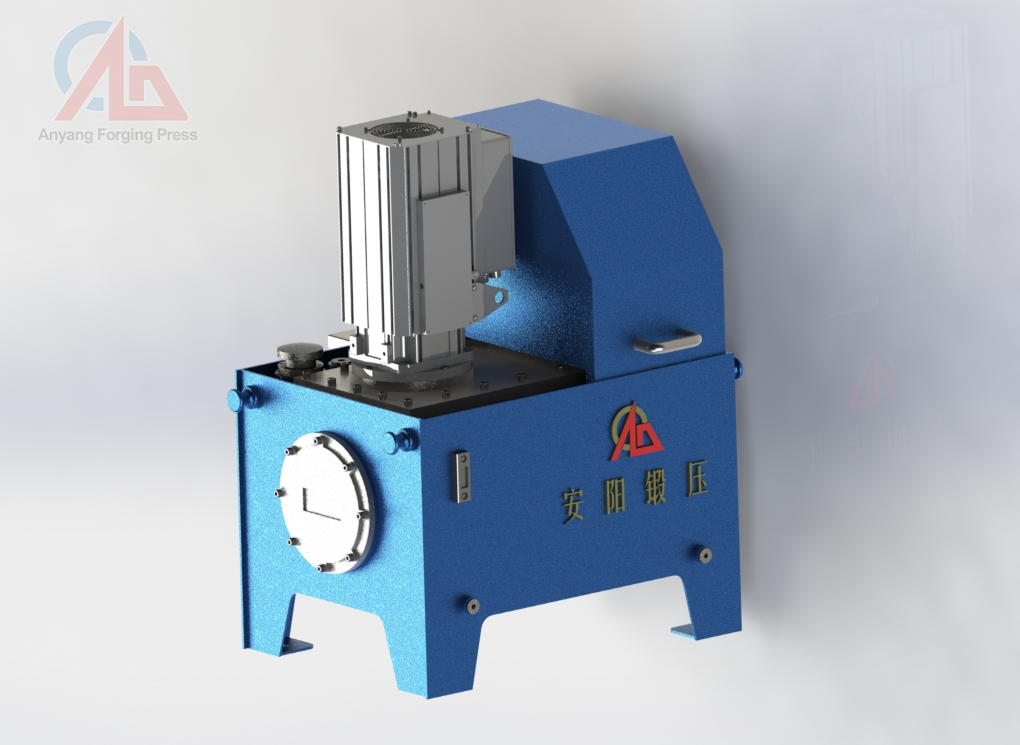

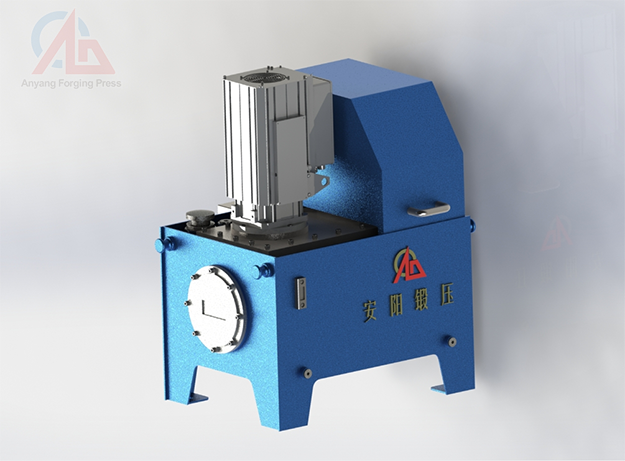

- Hydraulic Riveting Machine

- Metal Chips Briquetting Press (Y83)

- Ring Rolling Machine (D51-Vertical)

- Metal Scrap Baling Press (Y81)

- Scale Removal Device

- ZHJ Mobile Charging Manipulator

- ZHJ Rail Bound Charging Manipulator

- Contact Us