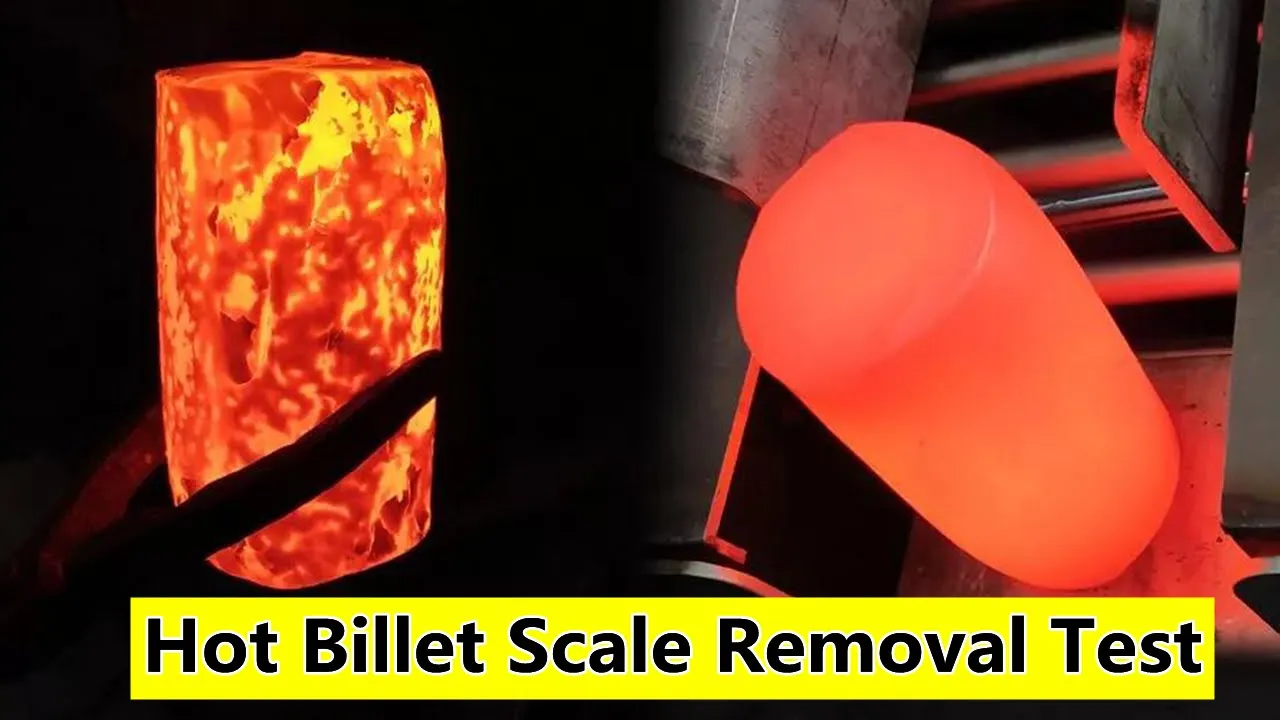

After the forging is heated, the air surface temperature is relatively high, usually around 1100°C. At this time, the forging will react with the oxide skin when it contacts with the oxygen in the air, thus forming the product of the oxide scale. During the forging process, the oxide scale It is a dangerous factor for forgings, because the scale will be brought into the workpiece during forging, which will reduce the quality of forgings and cause internal defects.

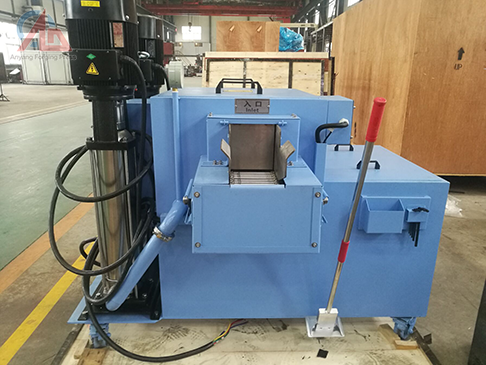

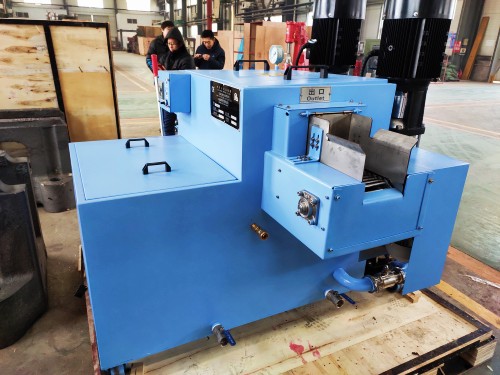

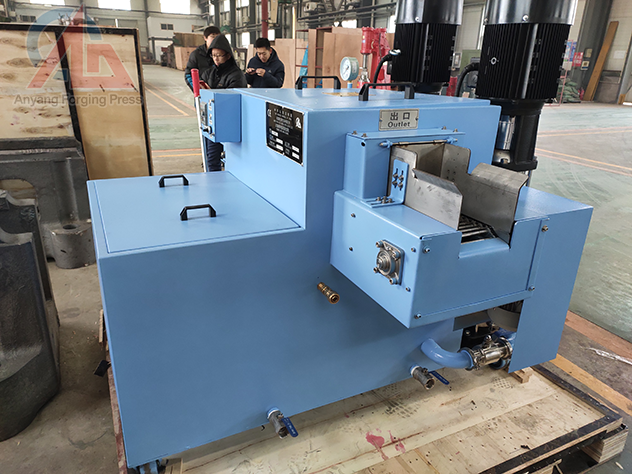

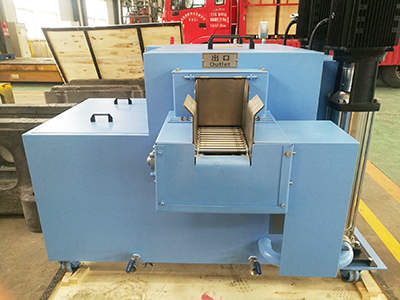

The forging phosphorus removal machine can effectively improve the surface quality of forgings. The forging phosphorus removal machine uses the principle of high-pressure water phosphorus removal to remove the oxide skin on the surface of the forging, so that no oxide skin will fall into the mold during the forging process, and avoid damage to the mold caused by the excessive oxide skin , thereby improving the service life of the mold.

If you are interested in it, pls contact me.

Felicia

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870