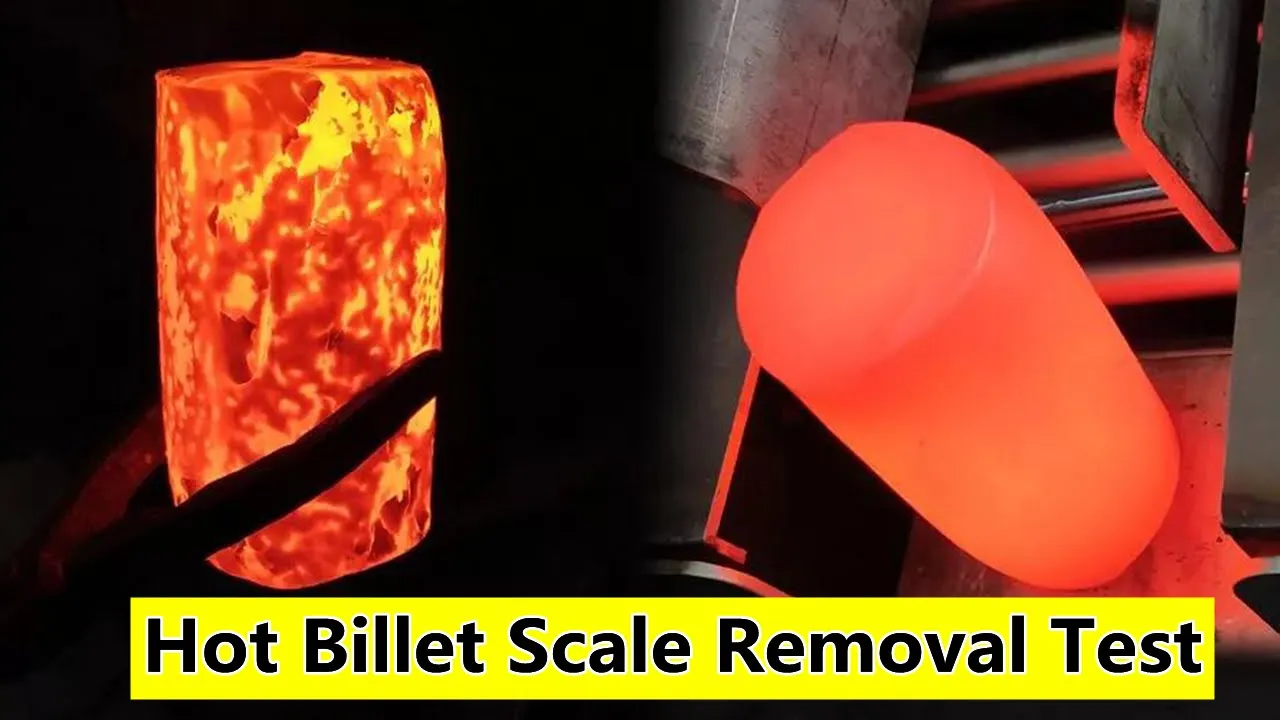

In the process of forging, the above-mentioned oxide scale will be produced after the material is heated. This oxide scale belongs to furnace oxide scale. The above-mentioned oxide scale is attached to the surface of the forging. What is the role of these oxide scales during forging? It will be pressed into the inside of the forging by the press, causing a lot of slag inside the forging, thereby affecting the quality of the forging, causing defects in the forging, and seriously causing it to become scrap. Therefore, the oxide scale produced in the forging will have these counter-effects.

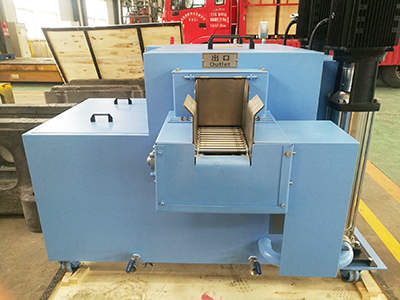

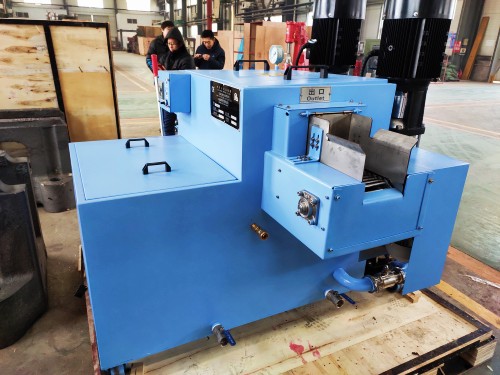

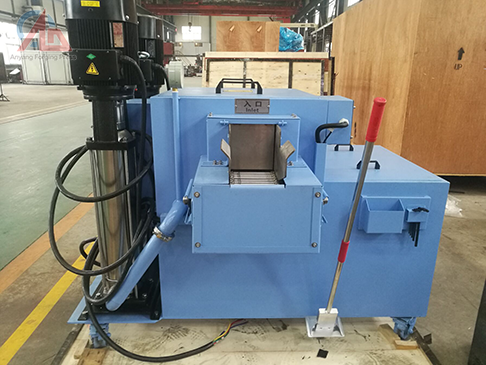

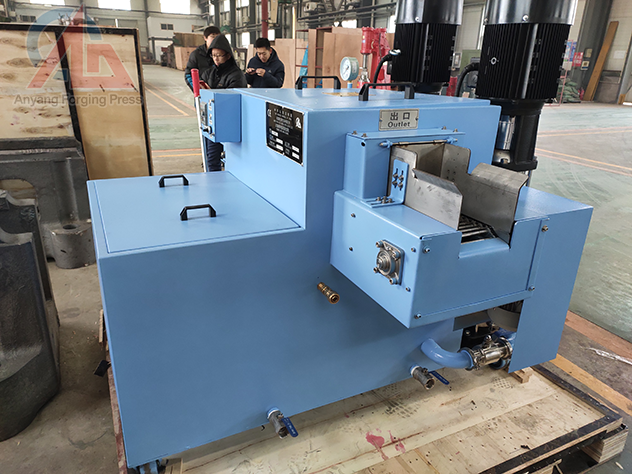

The metal descaling machine is developed according to the high-pressure water dephosphorization system. It can replace the manual high-pressure water dephosphorization method to remove the scale. A product can be produced in about 3 seconds, which is faster and cleaner than manual steel brush descaling. The speed is fast and the temperature drop is small. The purpose of the scale cleaning machine is to remove the scale on the surface of the forging, which can make the forging more beautiful and the product quality better.

Felicia

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.