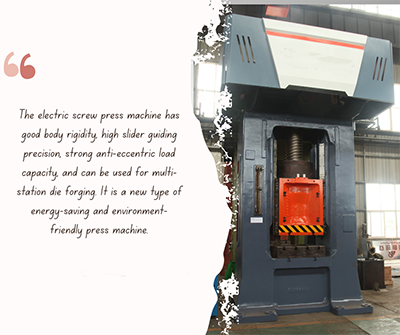

In the field of modern mechanical manufacturing, the crankshaft is the core component of the engine, and its manufacturing process directly determines the performance and life of the engine. With the continuous advancement of forging technology, electric screw presses, as an advanced forging equipment, are becoming an ideal choice for crankshaft manufacturing.

The following are the core advantages and application value of electric screw press in crankshaft forging:

1. High-precision forging to ensure crankshaft quality

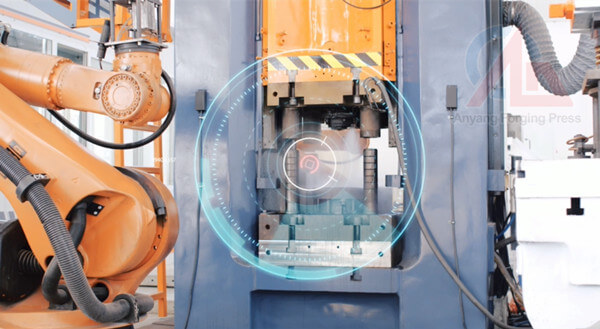

The crankshaft has a complex geometric shape and extremely high dimensional accuracy requirements. The electric screw press can achieve precise control of hammer force and displacement through a digital control system to ensure that each forging can achieve the size and shape required by the design. This high-precision forging method effectively reduces the amount of subsequent processing while improving the strength and fatigue life of the crankshaft.

2. High-efficiency production and improved manufacturing efficiency

The electric screw press adopts an advanced continuously variable speed motor drive, which can complete high-energy hammering in a short time, significantly shortening the forging cycle of the crankshaft. Its continuous and stable working ability ensures high efficiency and consistency in mass production, meeting the needs of modern manufacturing for high efficiency.

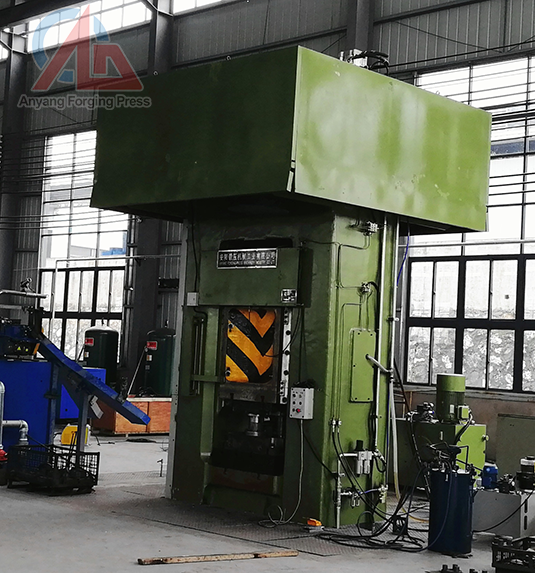

3. Low energy consumption, lower production costs

Compared with traditional hydraulic or mechanical presses, electric screw presses have higher energy conversion efficiency and lower energy consumption. Its intelligent energy management system can adjust the output power according to actual needs, avoid energy waste, help enterprises reduce production costs and achieve green manufacturing.

4. Low noise and low vibration, improve the working environment

The electric screw press has low noise and low vibration during operation, providing operators with a more comfortable and safe working environment. At the same time, its stable operation also reduces the impact on the equipment itself and other production equipment, and extends the service life of the equipment.

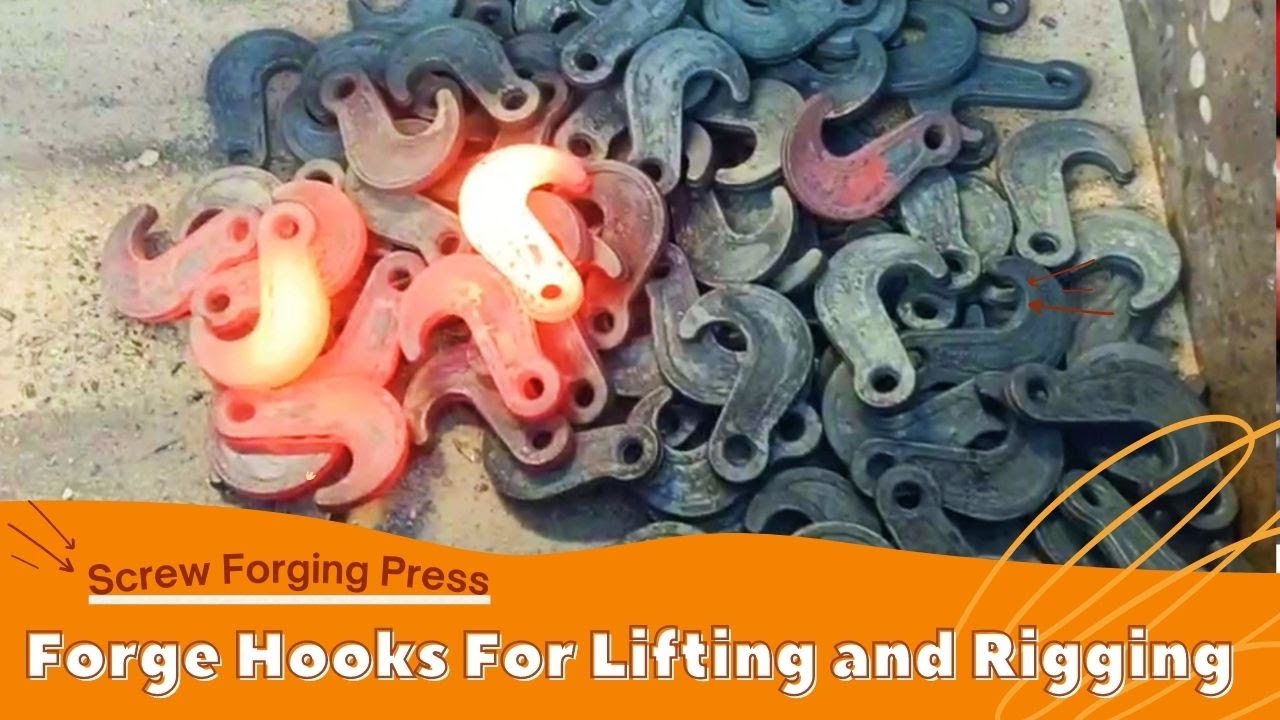

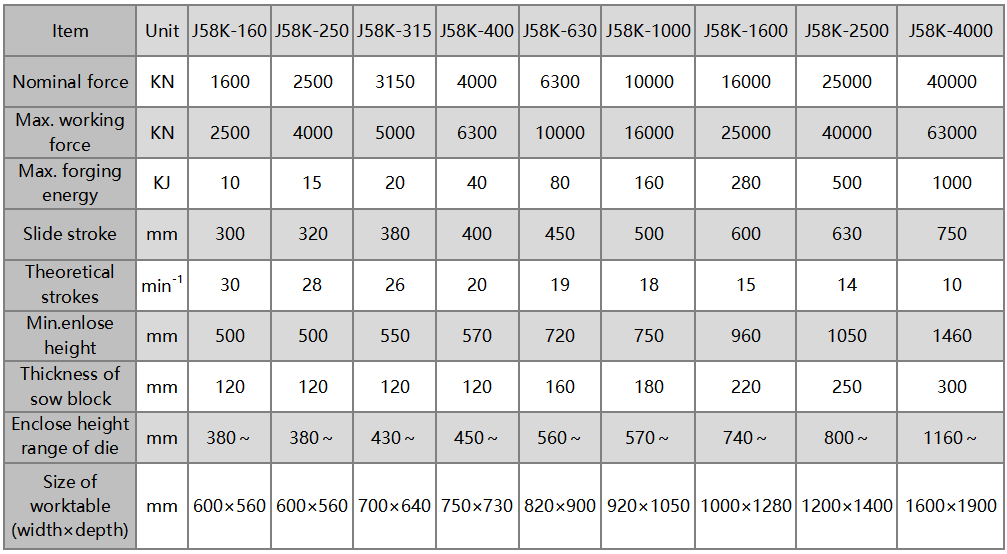

5. High flexibility, adaptable to a variety of crankshaft specifications

The electric screw press can achieve forging of different crankshaft specifications through program adjustment, and has strong adaptability. Whether it is a small engine crankshaft or a large ship engine crankshaft, it can be easily dealt with by adjusting parameters to meet the flexibility requirements of multi-variety and small batch production.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.