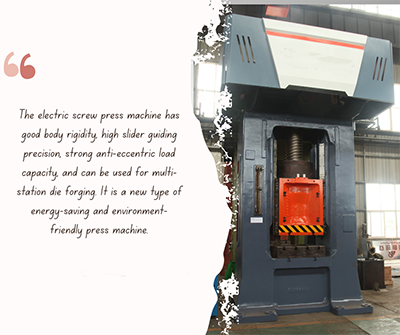

Electric screw press is a kind of equipment used in forging industry. Screw press has the characteristics of great versatility, simple structure, easy adjustment and maintenance, no bottom dead point of slider, convenient mold design, high precision of forgings, etc. It is suitable for various processes such as fine forging, finishing, fine pressing, stamping, straightening, and leveling.

Process flow of forging golf club heads with electric screw press

1. Raw material preparation

Golf clubs usually use materials such as aluminum alloy, titanium alloy or stainless steel. First, the raw materials are processed into blanks suitable for forging to ensure that their shape and size are suitable for subsequent processes.

2. Heating treatment

Heating the blank to the appropriate forging temperature can improve the plasticity of the material and facilitate subsequent forming processing.

3. Forging operation

Put the heated blank into the electric screw press for forging:

Preliminary forging: Apply initial pressure in the press to make the material start to flow and form a general shape.

Finish forging: Continue to apply pressure to make the forging closer to the final shape while ensuring dimensional accuracy and surface quality. The superior control ability of the electric screw press ensures this.

In the forging of golf club heads, the electric screw press can not only provide high-quality forgings, but also significantly improve production efficiency. With the advancement of technology, electric screw presses will be more widely used in the field of high-end metal forging.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.