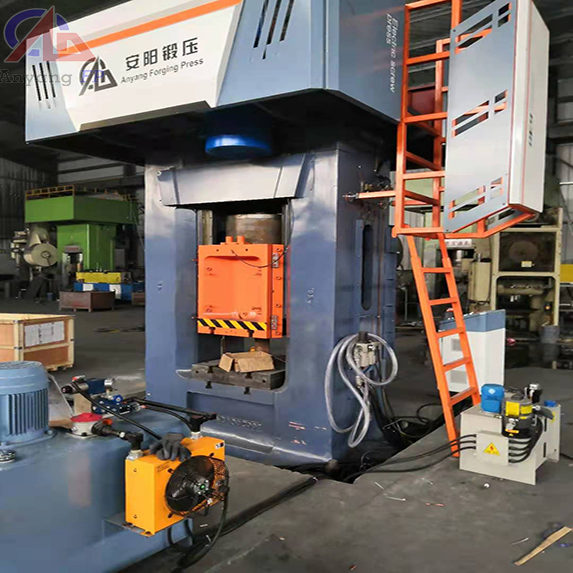

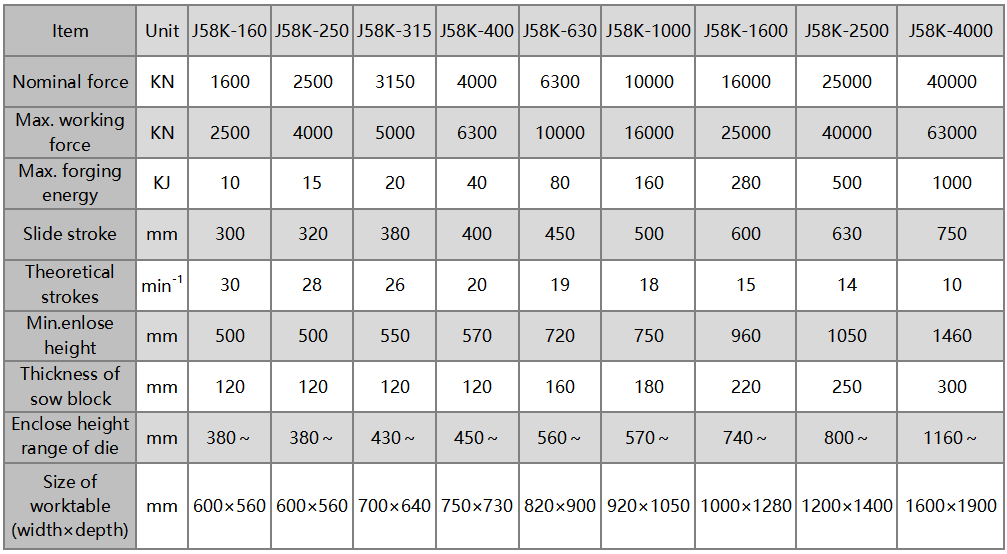

The J58K series electric screw press is a highly efficient and precise forging equipment, which is widely used in the fields of automotive parts, aerospace, hardware tool manufacturing, etc. Its core advantage is that it combines the working principle of electric drive and screw press to provide a highly efficient, precise and energy-saving forging solution.

J58K series electric screw press core forging advantages

High-precision forming

The electric screw press has extremely high control accuracy and can achieve precise control of forging pressure, stroke and speed. This precision ensures the consistency of workpiece size and is particularly suitable for the production of high-precision parts.

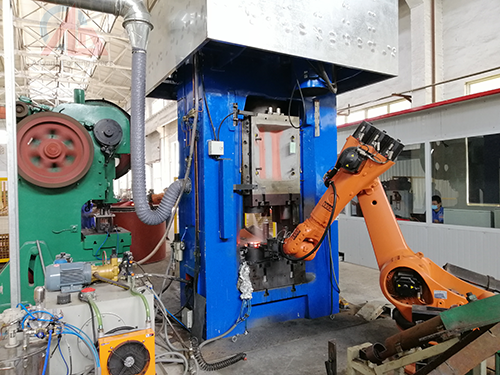

High-efficiency production

The 400-ton forging force can meet the forging needs of medium and large workpieces. At the same time, the electric drive system has a fast response speed and a high striking frequency, which greatly improves production efficiency.

Energy saving and environmental protection

Compared with traditional hydraulic presses or mechanical presses, electric screw presses are driven by electricity and only consume energy during the forging process. They have low energy consumption and low operating costs, which meet the requirements of green manufacturing.

Flexible operation

The pressure, stroke and speed of the electric screw press can be adjusted according to the needs of different workpieces. It is suitable for a variety of forging processes and has strong adaptability and flexibility.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.