Each step of forging the steering knuckle arm of an automobile with a hydraulic die forging hammer has an important impact on the quality and performance of the final product. The following is the general process flow of forging the steering knuckle arm of an automobile with a die forging hammer:

1. Material selection: High-strength carbon steel or alloy steel is usually selected. According to the design requirements and use environment of the steering knuckle arm, 35CrMo, 45# or other alloy steels are usually selected.

2. Material preparation: Cut the material into appropriate billets according to the size requirements of the forged part.

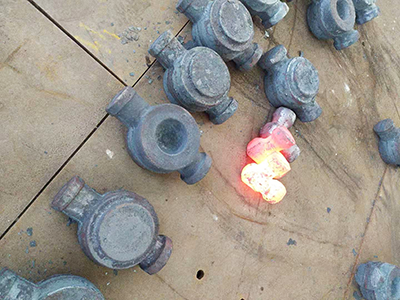

3. Heating: Use an induction heating furnace or a gas furnace for heating. At this stage, ensure that the material is evenly heated for subsequent forging.

4. Die design: Design the die according to the shape and size of the steering knuckle arm to ensure that the die has good exhaust performance and forming effect.

5. Forging process

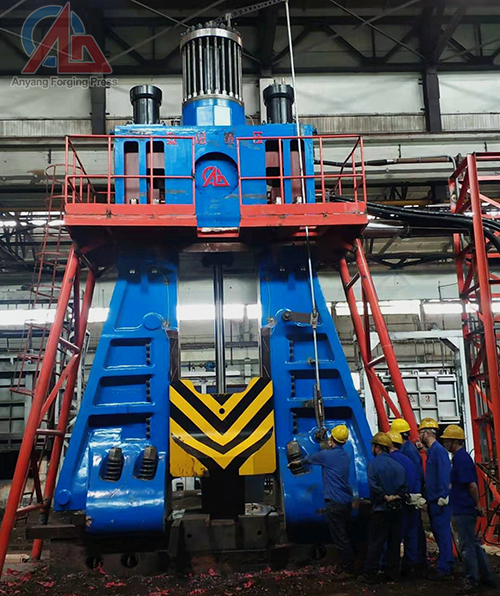

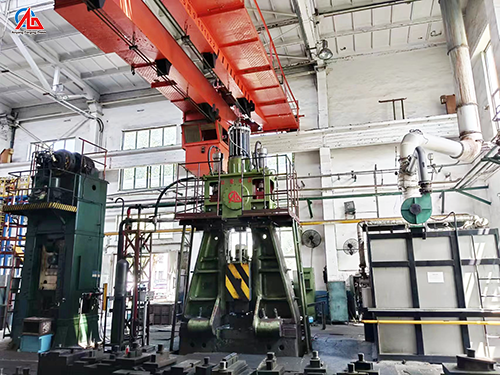

Die hammer device: Put the heated metal billet into the die and use the die forging hammer for forging.

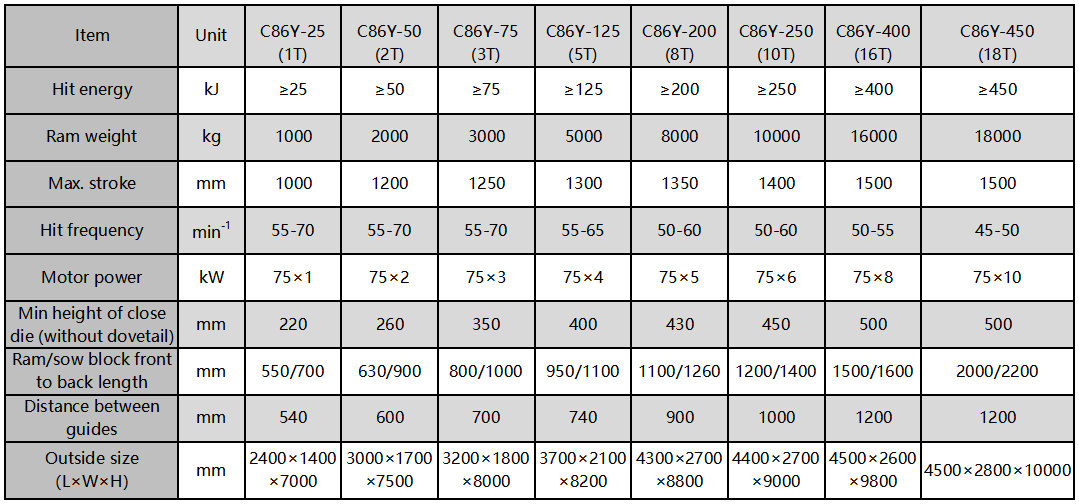

Hammering process: According to the design and material properties of the die, control the speed and frequency of the hammering to ensure sufficient deformation and achieve the predetermined shape. At this stage, attention should be paid to the forging temperature to avoid overheating or cooling of the material too quickly.

Finalizing: Through multiple hammering, the steering knuckle arm reaches the precise shape of the design.

6. Cooling: Controlled cooling is adopted as needed to reduce internal stress.

7. Heat treatment: Heat treatment is carried out at a certain temperature to improve the toughness of the material and reduce brittleness.

8. Machining: Milling, turning and other machining are carried out on the forged parts to achieve the precise requirements of size and surface finish.

9. Surface treatment

10. Inspection and quality control

11. Deliver qualified steering knuckle arms to customers or enter the next process.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.