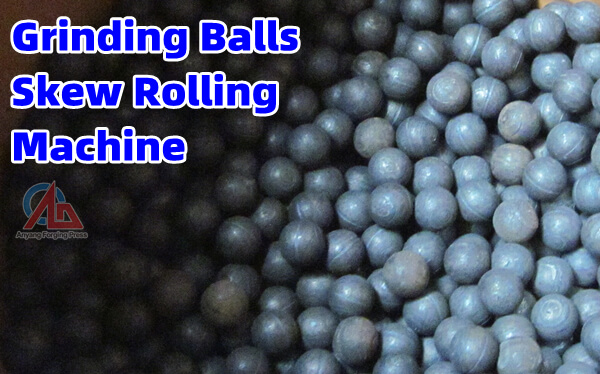

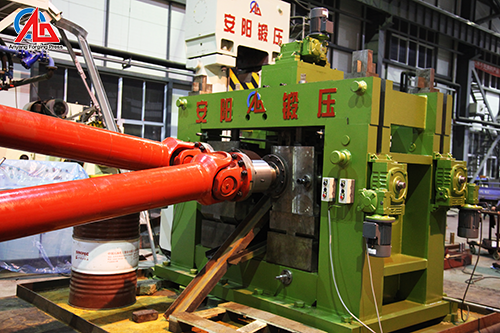

Skew rolling mill production line used to produce steel balls or steel forging. The angle between the two rolls of the skew rolling mill is generally 2 ° -6 °. The roll has a spiral hole pattern. When the two rolls are rotated in the same direction, the round billet rotates reversely with the roll between the rolls and advances through the spiral hole Round bar rolled into the desired shape. Then after the heat treatment process to meet the requirements of grinding steel ball.

Steel ball skew rolling principle:

The work principle of helical hole type cross rolling is shown in the figure. Two axes with helical hole cross each other. The rollers rotate in the same direction to rotate and advance the circular piece, under the action of forming rotary parts blanks. Skew rolling deformation is mainly axial compression of the axial extension.

If you are interested in it, please contact me.

Luking

Luking@anyanghammer.com

WeChat: +86-16692292860