In traditional forging workshops, workers need to operate bulky forging equipment, which is labor-intensive and difficult to guarantee production efficiency and safety. The emergence of forging manipulators has brought revolutionary improvements to the forging industry.

Advantages of forging manipulators:

Automated operation: Forging manipulators can replace manual operations such as clamping, handling, and flipping, reduce workers’ labor intensity, improve production efficiency, and make your production easier and more efficient.

Precise positioning: High-precision servo control system to achieve precise positioning and stable control of forged workpieces, ensure forging accuracy, improve product quality, and help you create high-quality products.

Safe and reliable: Forging manipulators adopt safety protection design to effectively avoid industrial accidents, ensure workers’ safety, and create a safe and reliable production environment for you.

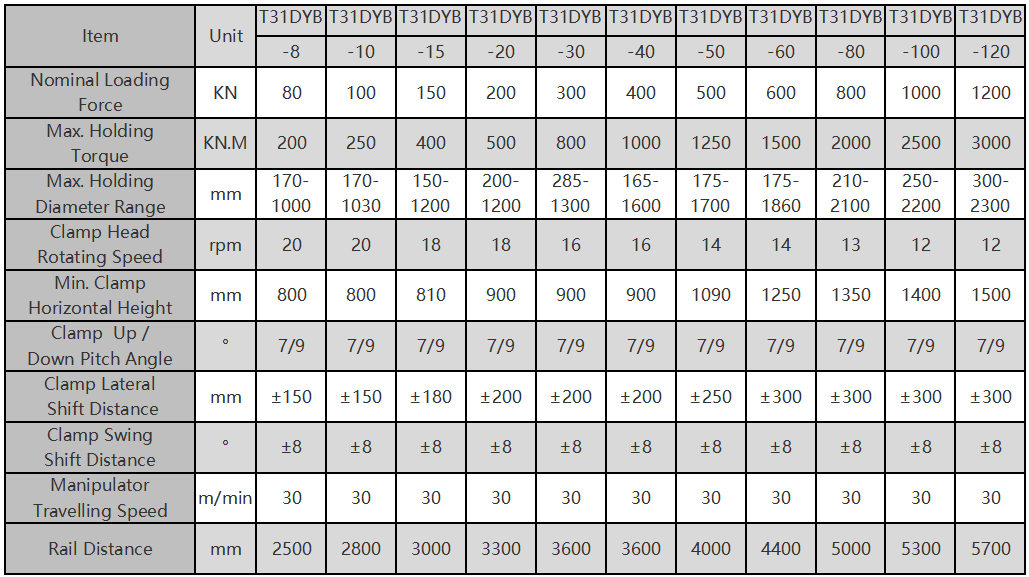

Flexible and changeable: A variety of models and specifications are available, which can be used with different models of forging equipment, suitable for various forging processes such as free forging, die forging, and ring rolling to meet your diverse needs.

Energy saving and environmental protection: Forging manipulators use high-efficiency energy-saving motors and hydraulic systems to reduce energy consumption, reduce production costs, and create greater economic benefits for you.

Application fields of forging manipulators:

Aerospace: Forging of key parts such as aircraft landing gear and engine blades;

Shipbuilding: Forging of large forgings such as marine crankshafts and rudders;

Automobile manufacturing: Forging of parts such as automobile wheels and connecting rods;

Power equipment: Forging of wind turbine main shafts and nuclear power equipment forgings;

Machinery manufacturing: Forging of various types of engineering machinery and mining machinery parts.

Forging manipulators, with their advantages of automation, precision, safety and efficiency, are becoming the inevitable choice of the modern forging industry.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.