The electric screw press is a forging equipment with strong process applicability. It takes into account the dual properties of forging hammer and press. It can adjust the striking energy according to the forming needs, reduce the mechanical stress and thermal stress of the mold, and extend the life of the mold.

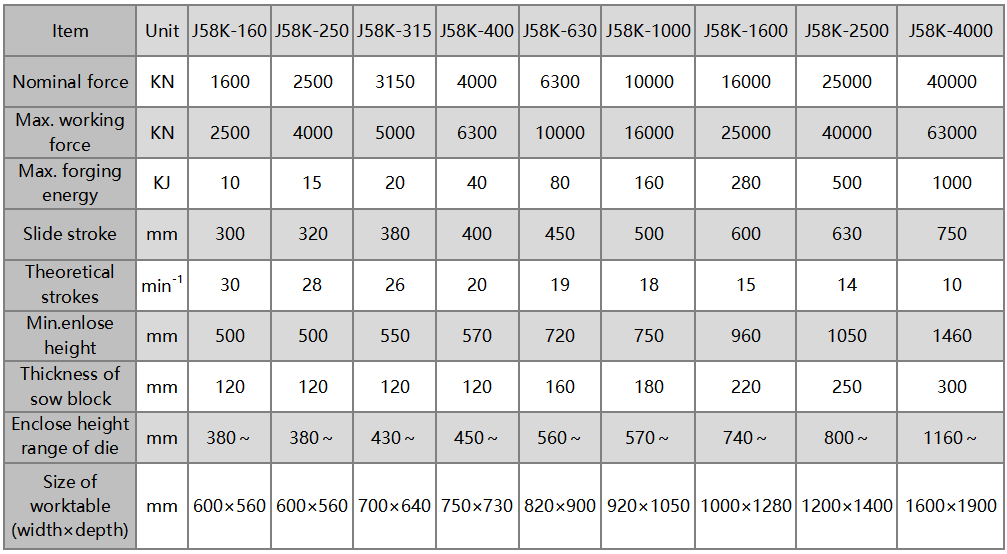

Core parameters of electric screw press:

Nominal force (KN)

Moving part energy (KJ)

Long-term operating allowable load (KN)

Slider stroke (MM)

Workbench size (front and back × left and right)

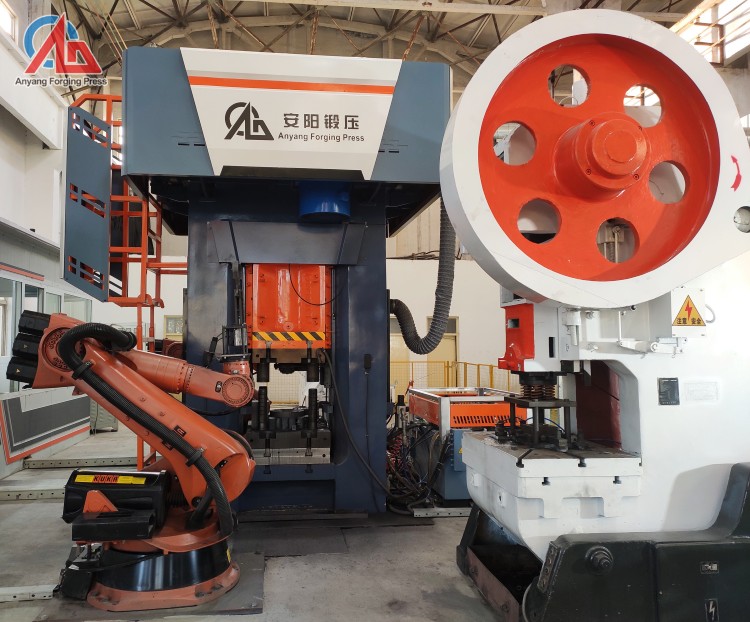

Electric screw presses are widely used in the following industries:

Automotive industry: production of engine components, transmission shaft components, gear components, brake disc components, etc.

Motor industry: production of motor micromotor components, etc.

Machinery industry: production of mechanical parts, automation components, etc.

Power industry: production of wind turbine blades, power fittings, parts, etc.

Aviation industry: production of turbine blades, special bolts and other parts.

Rigging industry: production of hooks, shackles, rings and other locks.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.