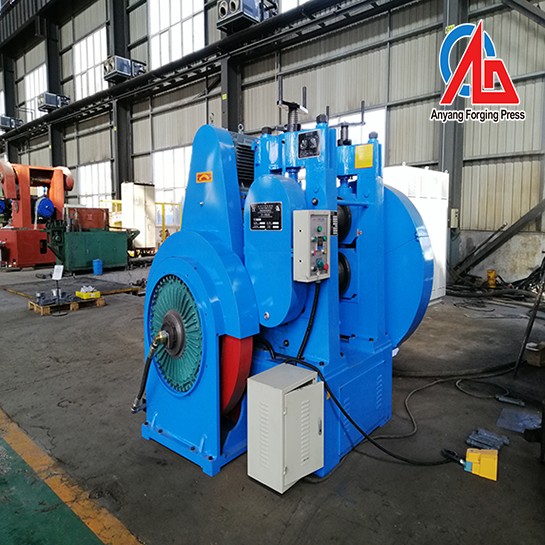

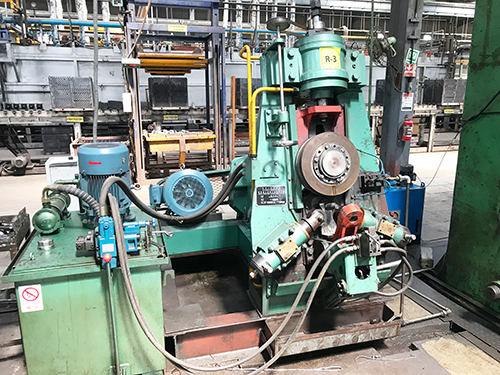

D51 Series Vertical Ring Rolling Machine Working Principle and Quotation

Vertical ring rolling machines are mainly used for the manufacture of metal rings and are widely used in the automotive, aerospace and machinery industries. Its working principle is as follows:

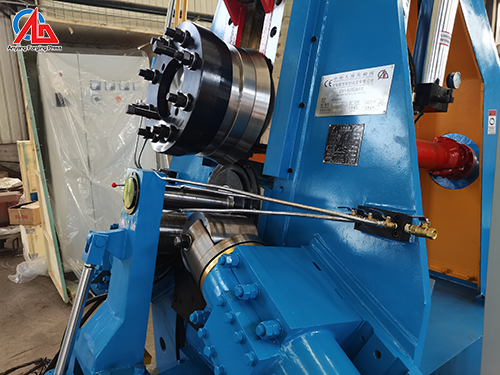

Material clamping: Fix the metal material (such as steel or aluminum) in the machine’s fixture to ensure that it does not move during processing.

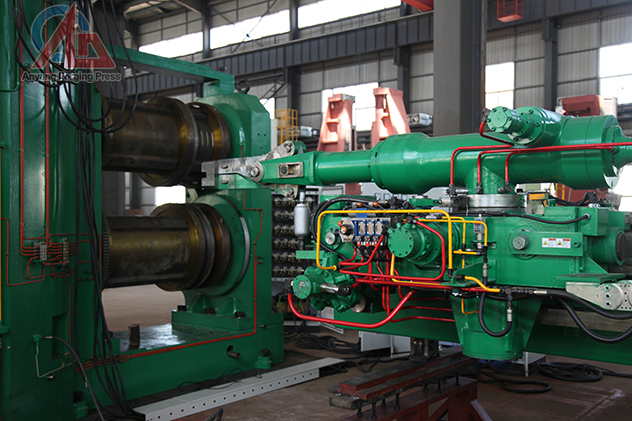

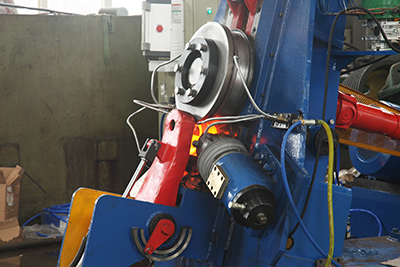

Forming process: The metal material is gradually deformed into a ring by applying pressure to the rollers of the vertical ring rolling machine. The rollers are usually conical to ensure that the metal is evenly stressed during processing.

Continue rolling: With the cooperation of the rotation and reciprocating motion of the rollers, the metal material is rolled into a predetermined wall thickness and diameter.

Inspection and adjustment: After the forming is completed, the finished product is inspected and the machine is fine-tuned as needed to ensure that the quality of the ring meets the standards.

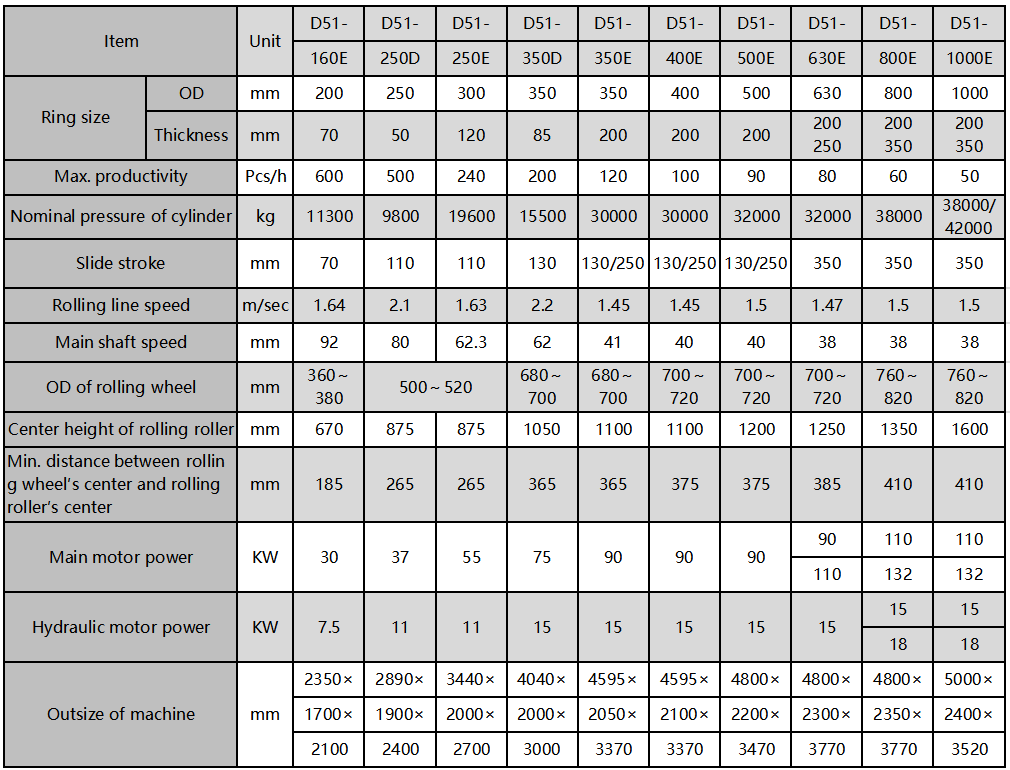

The price of vertical ring rolling machine varies depending on factors such as brand, model, function configuration and market supply and demand. In order to obtain a specific quotation, it is recommended that you contact us directly and explain your specific needs and application scenarios. This will not only help you understand the latest market prices, but also obtain detailed information about different models.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.