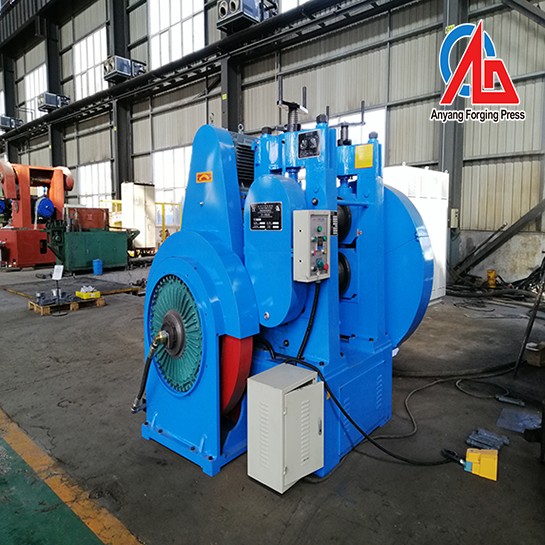

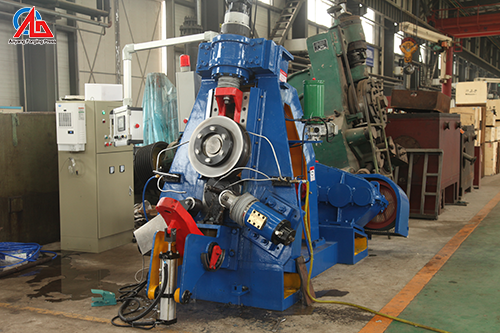

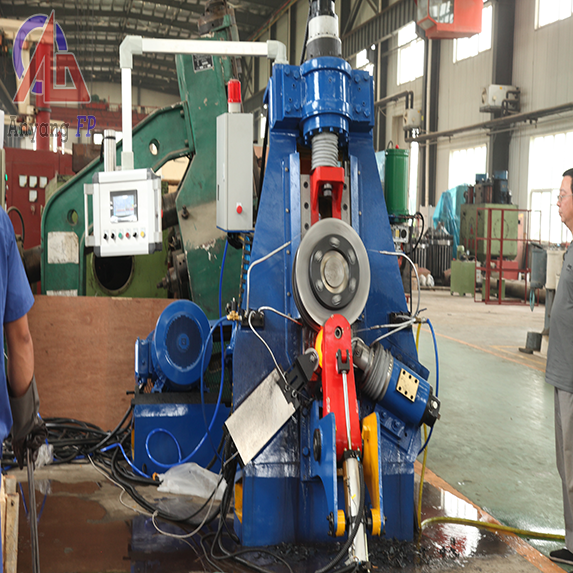

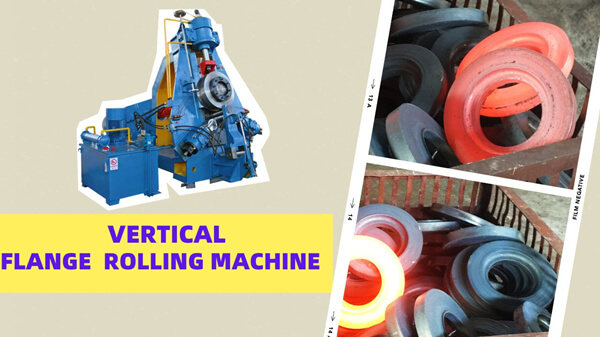

The advantage of the D51 series vertical ring rolling machine is that it can be mass-produced efficiently and accurately, while improving the density and material utilization of the product.

The process of forging high-neck flanges with a D51 series vertical ring rolling machine usually involves the following steps:

1. Raw material preparation: Select suitable metal materials, such as carbon steel, stainless steel or alloy materials, and cut them into appropriate sizes.

2. Heating: Heat the metal material to a temperature suitable for forging to improve its plasticity, usually achieved by an electric furnace or an induction heating furnace.

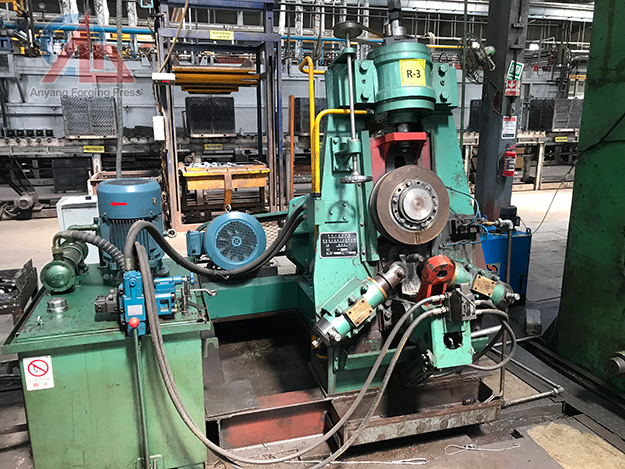

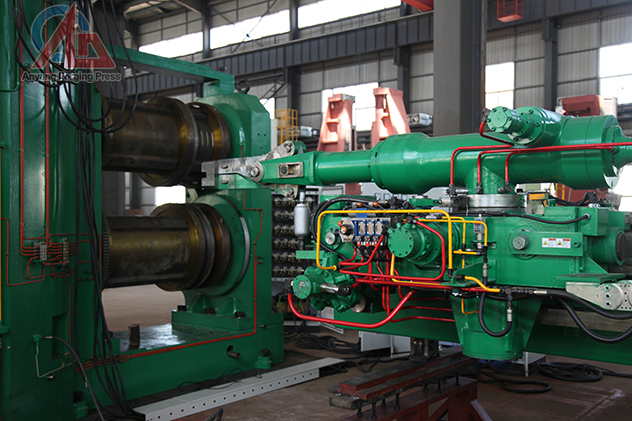

3. Rolling: Put the heated material into the mold of the ring rolling machine, and the machine will gradually form the material into the shape of a high-neck flange by rolling. In this process, the material is compressed and plastically deformed to form the required neck and flange edge.

4. Cooling: After forging, the flange needs to be cooled naturally or by cooling methods such as oil quenching to ensure its structural stability.

5. Post-processing: The flange after forging may require subsequent processing, such as deburring, heat treatment, surface treatment, etc., to improve its mechanical properties and corrosion resistance.

6. Quality inspection: Finally, the forged high-neck flange should be inspected strictly in accordance with relevant standards to ensure that its size, appearance and mechanical properties meet the requirements.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.