D51 Series Vertical Ring Rolling Machine Advantages and Applications of Forged Rings

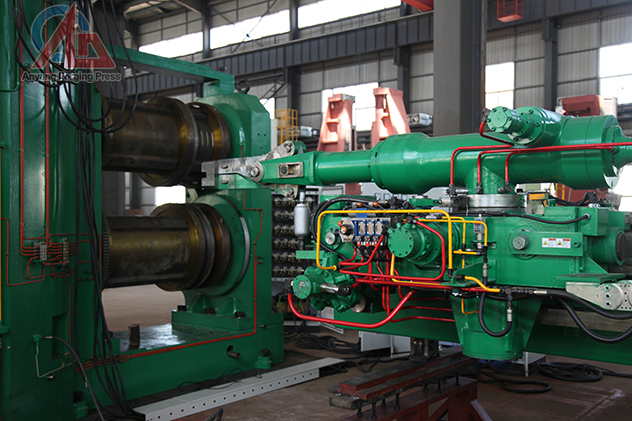

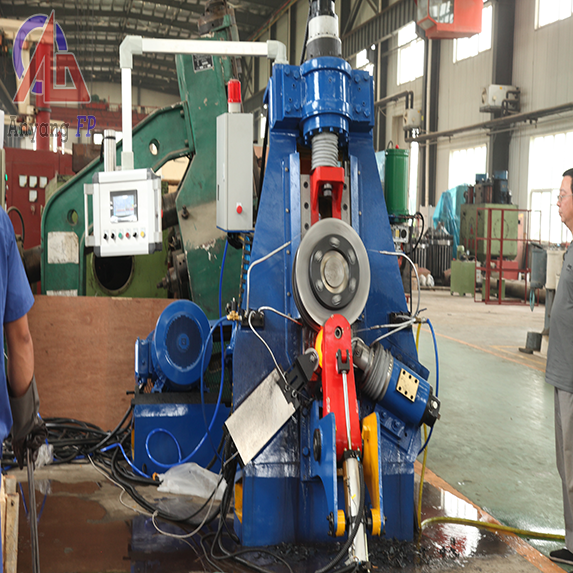

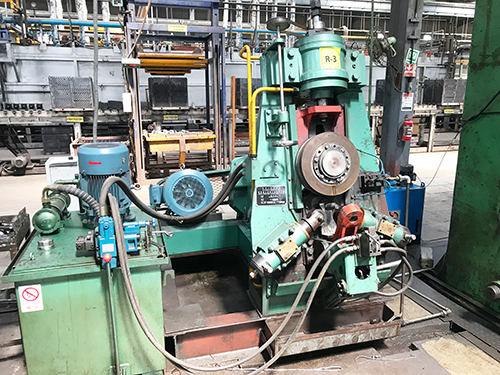

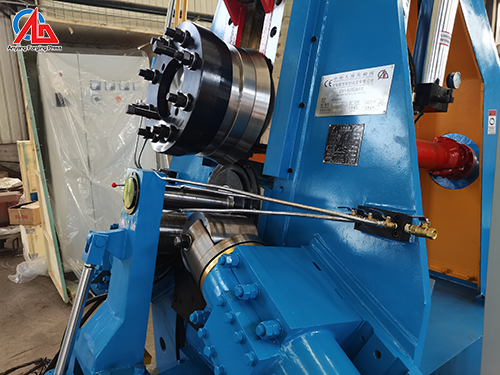

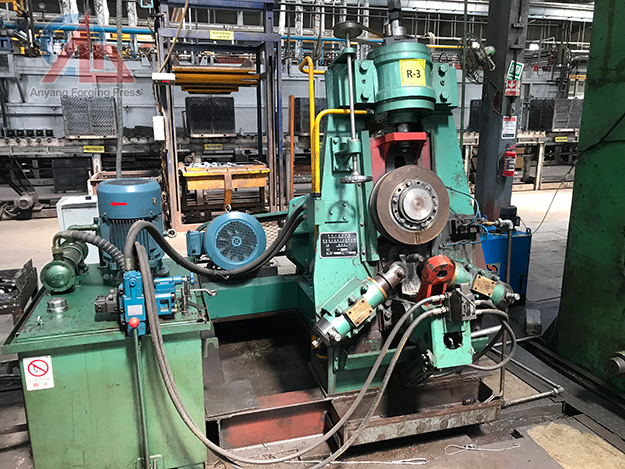

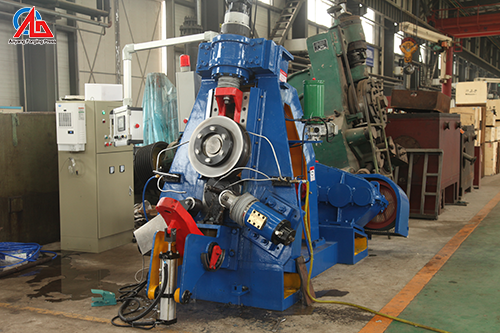

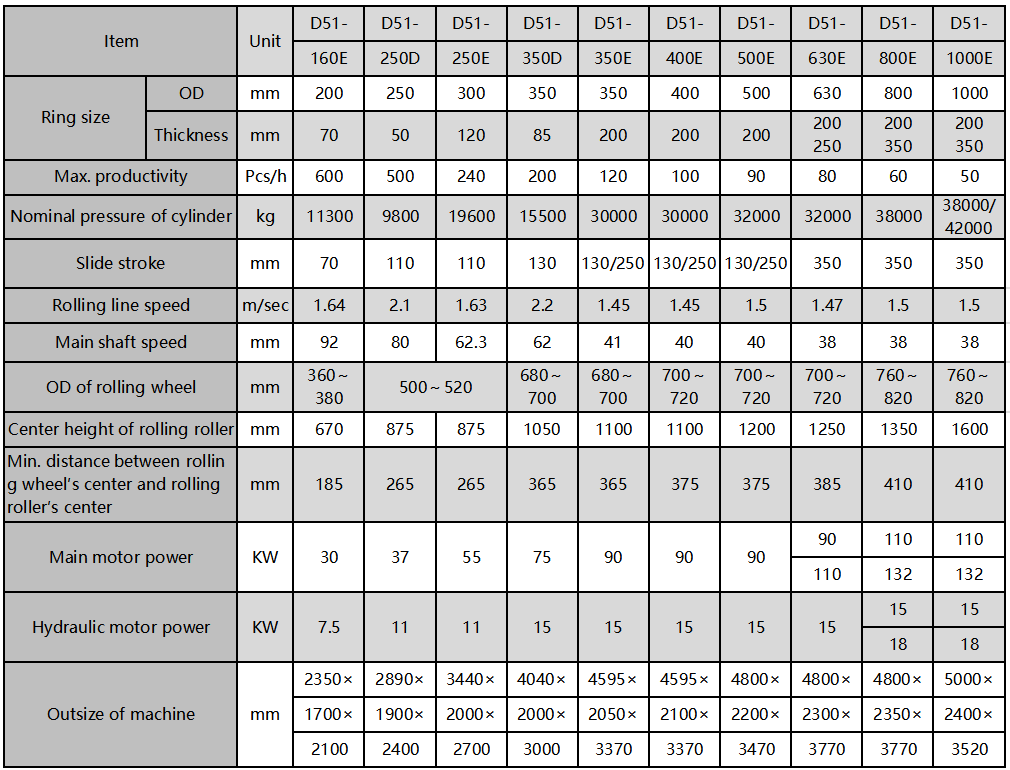

D51 series vertical ring rolling machine is a kind of high-efficiency and precision equipment used to manufacture ring forgings. It processes metal blanks into seamless rings through rolling process.

Advantages of D51 Series Vertical Ring Rolling Machine for Forged Rings

High Precision: The size, roundness and wall thickness of the rings can be precisely controlled, which is suitable for manufacturing rings with high precision requirements.

High Efficiency: Compared with traditional forging, it has high material utilization rate, short production cycle and is suitable for mass production.

Versatility: It supports the processing of a variety of metal materials (such as steel, aluminum alloy, titanium alloy, etc.) and complex cross-sectional shapes.

D51 Series Vertical Ring Rolling Machine Application Fields

Wind power: manufacturing wind power tower flanges, bearing rings, etc.

Aerospace: production of rocket fuel tank rings, engine casings, etc.

Energy: used for nuclear power pressure vessel support rings, hydropower rotor brackets, etc.

Heavy machinery: processing shield machine bearing rings, mining equipment rings, etc.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.