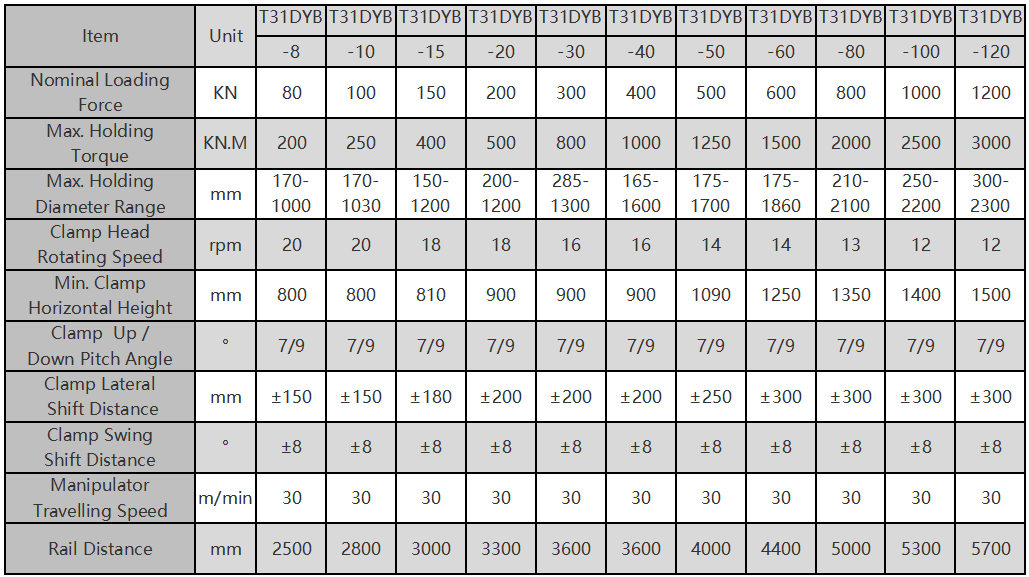

CNC forging manipulator is an important equipment in modern forging production line, mainly used to assist in the clamping, flipping, moving and positioning operations in the forging process. It can significantly improve production efficiency, reduce labor intensity, and ensure forging accuracy and safety.

CNC Forging Manipulator Features

Efficient Automation

The automated control system can achieve precise operation, reduce manual intervention, and improve production efficiency.

Versatility

It has multiple functions such as clamping, flipping, moving, and rotating, which can meet the needs of different forging processes.

High-precision positioning

Equipped with high-precision sensors and control systems to ensure accurate positioning of the workpiece during the forging process and improve product quality.

Strong carrying capacity

It can carry heavy workpieces and is suitable for the production of large forgings.

Safe and reliable

Equipped with safety protection devices and emergency stop functions to ensure the safety of operators and equipment.

CNC forging manipulators are widely used in the following industries:

Heavy machinery: such as the production of large equipment forgings such as ships, wind power, and nuclear power.

Automobile manufacturing: used for forging key parts such as engine crankshafts and connecting rods.

Aerospace: used for the production of high-precision and high-strength forgings.

Energy equipment: such as the forging of oil and natural gas pipelines and equipment.

General machinery: such as the forging of parts such as gears and bearings.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.