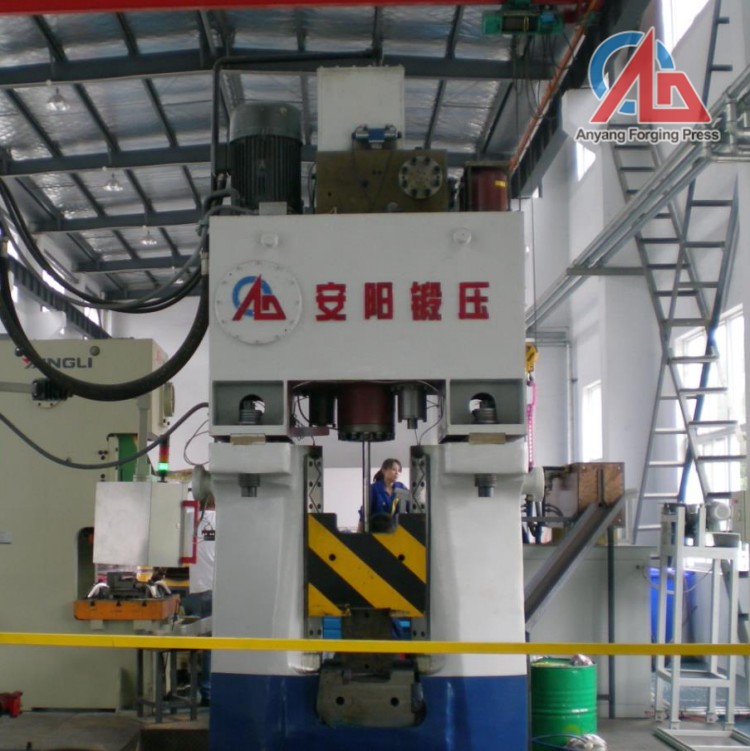

C92K series hydraulic Close Die Forging Hammer Technical advantages and applications

Hydraulic Close Die Forging Hammer (C92K) is a forging equipment driven by a hydraulic system. It is equipped with a CNC system and can perform high-precision striking and forming according to different forging requirements.

Technical advantages of Hydraulic Close Die Forging Hammer (C92K)

Intelligent CNC: Equipped with industrial-grade PLC+touch screen human-machine interface, it supports cloud storage and call of process parameters;

Dynamic response: Full hydraulic drive achieves millisecond response to ensure the density and surface finish of forgings;

Flexible production: Programmable multi-stage forging mode to meet the step forming requirements of precision forgings (such as gears and connecting rods);

Safety protection: Triple safety interlock (overpressure/overload/misoperation protection), in line with CE/ISO certification standards.

Hydraulic Close Die Forging Hammer (C92K) Core Application Areas

Automobile manufacturing: Mass production of high-strength forgings such as engine crankshafts, gearbox gears, and wheel hub bearings;

Aerospace: Precision molding of titanium alloy turbine discs, aluminum alloy fuselage structural parts, and key landing gear components;

Energy equipment: Processing of large corrosion-resistant forgings such as wind power main shafts, nuclear power valves, and oil and gas drilling tools;

High-end hardware: Flexible manufacturing of multiple varieties and small batches of tool fixtures, hydraulic joints, and stainless steel special-shaped parts.

Felicia

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.