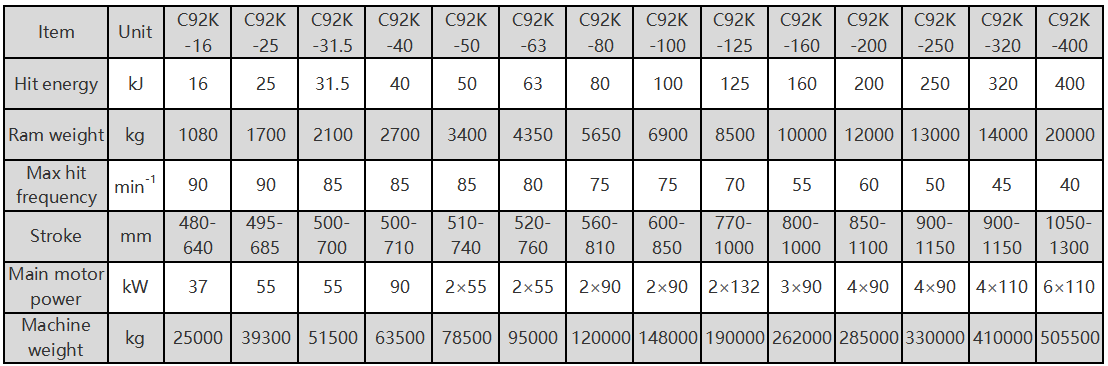

The advantages of C92K series CNC hammer forging connecting rods are mainly reflected in the following aspects:

Improve production efficiency

Fast processing: CNC hammers have high-frequency hammering capabilities, which can complete a large number of forgings in a short time, significantly improving production efficiency.

Automated operation: CNC systems reduce manual intervention and operate stably for a long time, which is conducive to mass production.

High precision

Dimensional control: CNC hammers can accurately input and adjust parameters to ensure that the size and shape of forged parts meet design requirements and reduce processing errors.

Consistency: Through automation and CNC technology, the size, shape and quality of each connecting rod are consistent, reducing the differences between products in the same batch.

High material utilization rate

CNC hammers can optimize the distribution and use of materials during the forging process and reduce the generation of waste.

Energy saving and high efficiency

Due to its high efficiency, CNC hammers also save costs on energy use and meet environmental standards.

The fully hydraulic CNC hammer forged connecting rod has shown significant advantages in production efficiency, quality control, material utilization and cost-effectiveness, making it an important process choice in modern manufacturing.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.