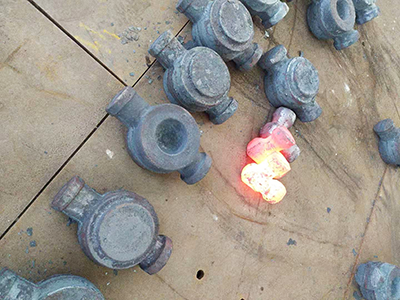

Hydraulic Closed Die Forging Hammer forging is an important metal forming process, which is widely used in aerospace, automobile, energy and other fields.

The core advantages of Hydraulic Closed Die Forging Hammer are mainly reflected in the following aspects:

High forming accuracy

Die forging hammer forging can achieve high-precision forming of complex-shaped parts through precise design of the die, reduce the amount of subsequent processing, and improve material utilization.

The forgings have stable dimensions and good surface quality, meeting the needs of high-precision parts.

Excellent mechanical properties

During the die forging process, metal materials undergo plastic deformation under high temperature and high pressure, grain refinement, and dense organization, which significantly improves the strength, toughness and fatigue properties of forgings.

The mechanical properties of forgings are better than those of castings and welded parts, and are suitable for high-load and high-stress working environments.

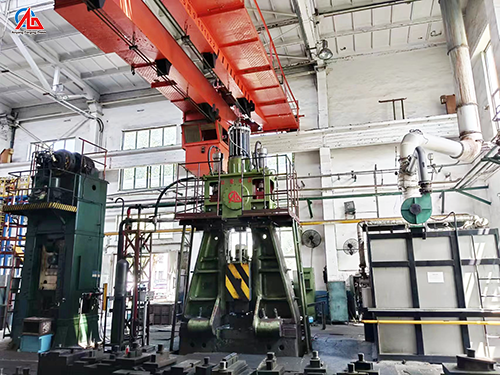

High production efficiency

Die forging hammer forging uses mechanized or automated equipment, which can quickly complete mass production and is suitable for large-scale manufacturing.

Compared with free forging, die forging has a shorter production cycle and higher efficiency.

High material utilization rate

The die forging process reduces material waste, improves material utilization rate and reduces production costs through precise die design.

The shape of the forging is close to the final product, reducing the amount of subsequent processing.

Strong adaptability

Die forging hammer forging is suitable for a variety of metal materials, including steel, aluminum alloy, titanium alloy, copper alloy, etc.

Die forging hammer forging has become an indispensable process technology in modern manufacturing due to its high precision, high performance, high efficiency and high reliability. Its core advantage is that it can meet the strict requirements of material performance and part quality in the field of high-end manufacturing, while reducing production costs and improving production efficiency.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.