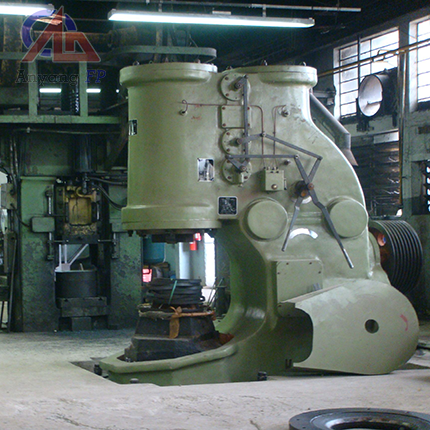

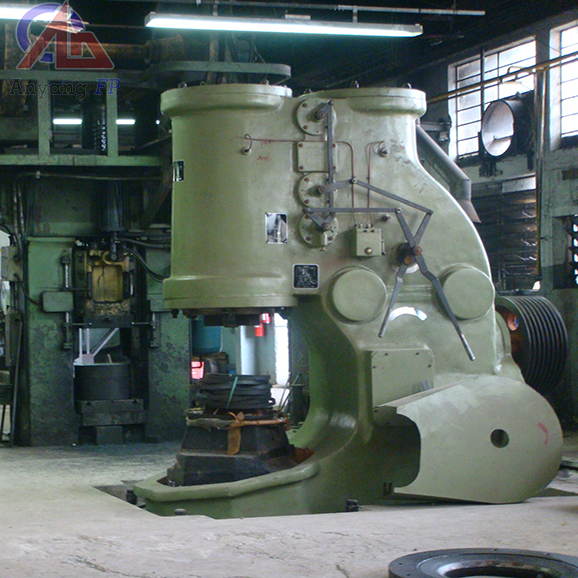

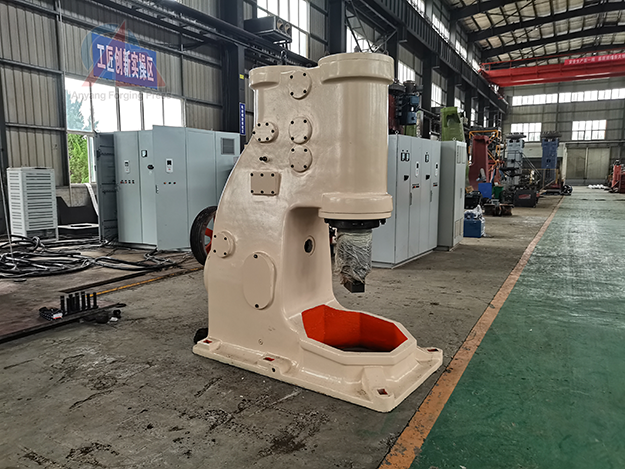

The C41 series pneumatic forging hammer is a forging equipment that uses compressed air as a power source and is widely used in metal forging processes.

Working principle of the C41 series pneumatic forging hammer

Power source: Compressed air is generated by an air compressor and stored in an air tank as the power source of the forging hammer.

Cylinder and piston: Compressed air enters the cylinder and pushes the piston up and down.

Strike process:

Rising stage: Compressed air enters the lower part of the cylinder, pushing the piston up and the hammer head up.

Descending stage: Compressed air enters the upper part of the cylinder, pushing the piston down quickly, and the hammer head exerts impact force on the workpiece.

Energy transfer: The impact force of the hammer head is transmitted to the workpiece through the anvil, causing plastic deformation of the metal blank.

Control system: By adjusting the intake valve and exhaust valve, the piston movement speed and striking force are controlled.

Application areas of the C41 series pneumatic forging hammer

Metal forging: used for free forging and die forging processes, such as upsetting, drawing, punching, bending, etc.

Suitable for forging steel, aluminum alloy, copper alloy and other metal materials.

Automobile manufacturing: used to produce automobile parts, such as crankshafts, connecting rods, gears, wheels, etc.

Aerospace: used to forge high-strength, high-precision aviation parts, such as engine blades, landing gear, etc.

Machinery manufacturing: used to produce various mechanical parts, such as bearings, flanges, valves, etc.

Tool manufacturing: used to forge hammers, wrenches, pliers and other hand tools.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.