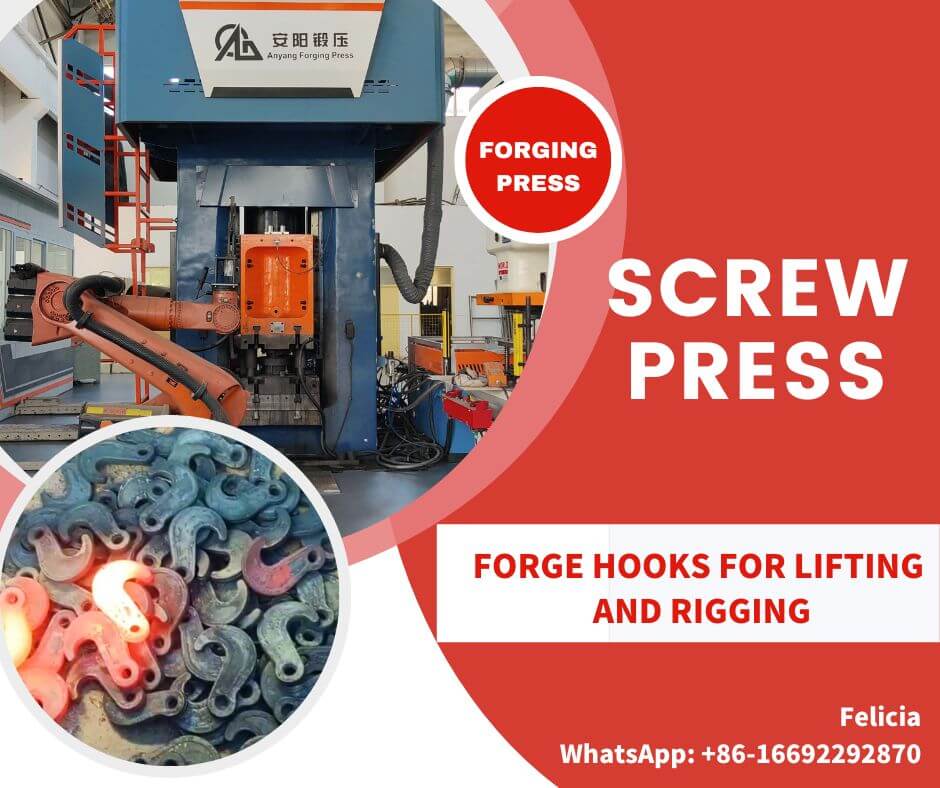

Electric Screw Press for Forging Line in Russia

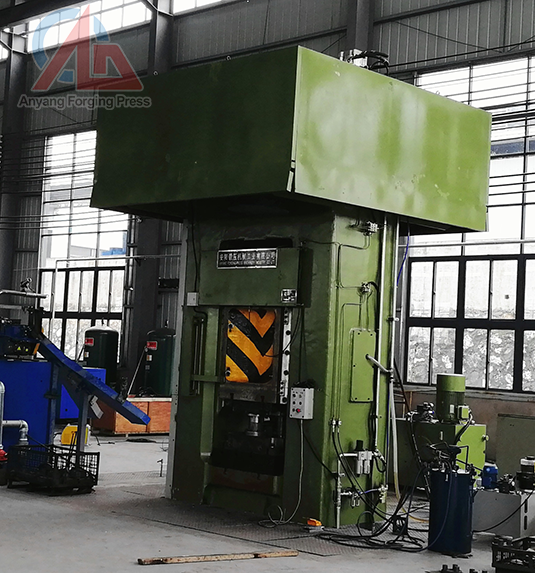

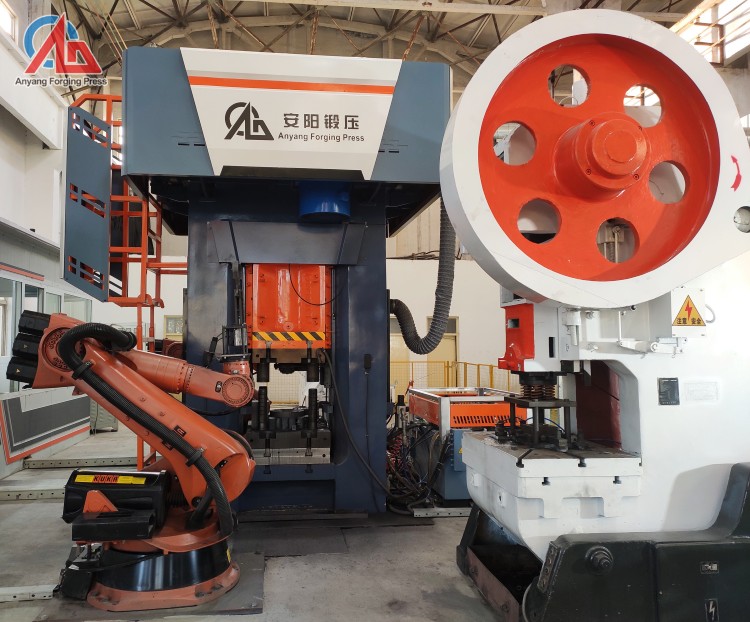

This production line includes a 1000Kw induction furnace, a J58K-1600 CNC electric screw press, a 400t trimming press, a D51-800 ring rolling machine, and two KUKA robots. It is mainly used to manufacture petroleum pipes. Production technology, equipment, and molds are provided by Anyang Forging Press Numerical Control Equipment Co., Ltd, with a production line output of 30 pieces per hour.

Why use an Automatic Hot Forging Line?

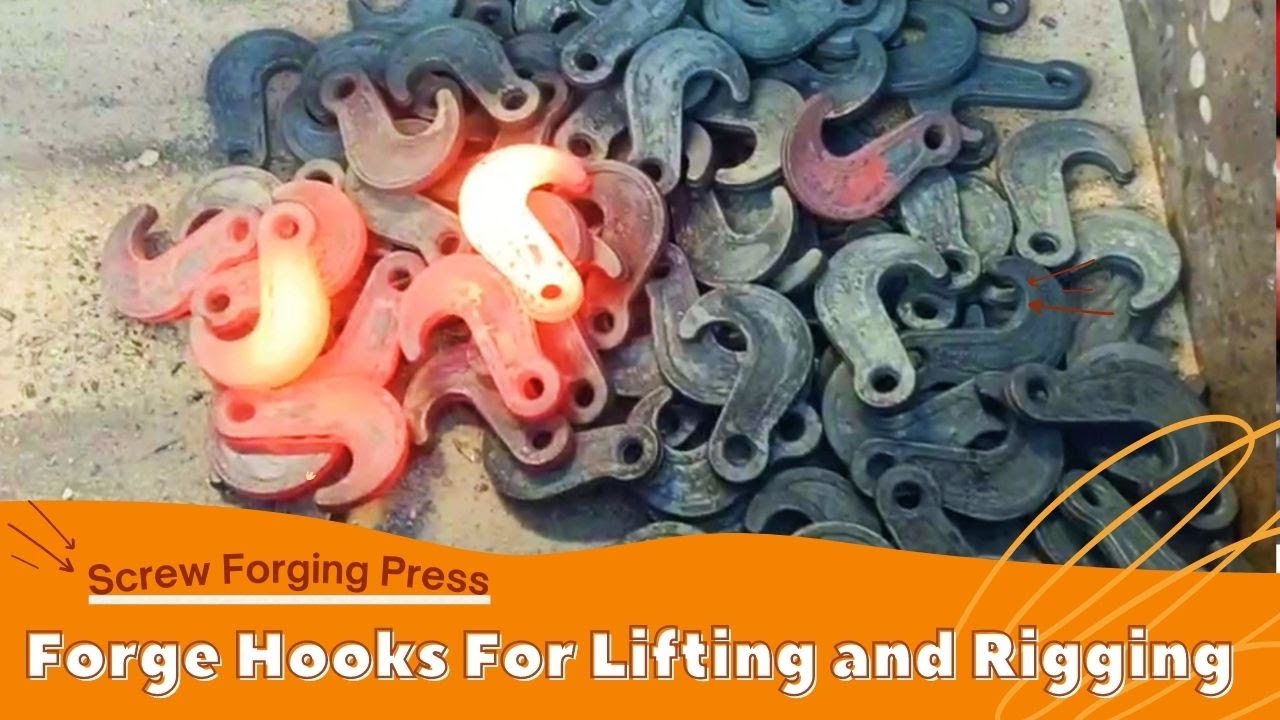

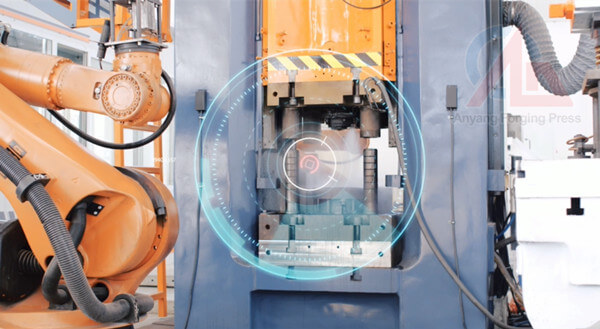

1. Ensure production safety by avoiding the operator’s hands being put into forging areas, using automatic inspection systems, and automatic protection devices, to prevent damage to the machine and dies.

2. Improve production efficiency: automatic continuous production, improve production efficiency, improve labor efficiency, decrease production costs, extend die life.

3. Ensure production consistency and improve product quality with robots’ automatic production and operation accuracy.

4. Can reduce labor costs.

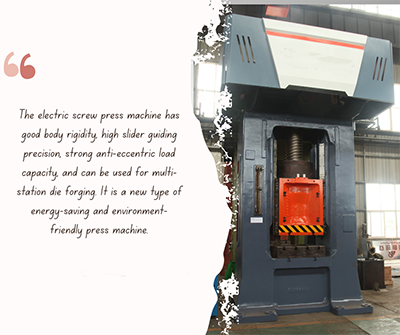

The J58K series CNC electric screw press has the following advantages over friction screw presses:

1. As compared to friction presses, energy savings are 30%.

2. Energy control that is precise.

3. A precise blow energy setting ensures high repeatability.

4. Higher die lives owing to short pressure-contact times.

5. Suitability for automation.

***************************************************************************************************************************************************************

We can provide 9-2000kg Power Hammers.

If you are interested in it, pls contact me.

Felicia

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870