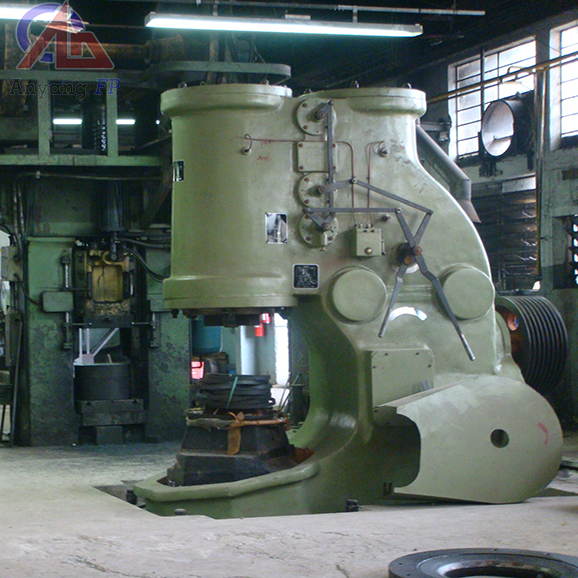

Anyang pneumatic hammer is a kind of free forging equipment, which has two cylinders: the compression cylinder (rear cylinder) compresses the air and sends it to the working cylinder (front cylinder) through the distribution valve, pushing the hammer rod and the hammer head to do up and down hammering. It is suitable for various free forgings: such as extension, upsetting, punching, shearing, forging welding, twisting, bending, etc., and various open die forging (tire die forging) can be performed using a cushion die.

Anyang pneumatic hammer is mainly composed of a fuselage, a transmission mechanism, a compression cylinder and a working cylinder, a compression piston, a drop part, a gas distribution mechanism and anvil.

Fuselage. The fuselage is the main body of the air hammer, and a transmission device, a working mechanism and a control mechanism are installed on the fuselage. These mechanisms are compactly combined into a whole on the frame.

Transmission mechanism. The transmission mechanism includes a pulley, a gear box, a crankshaft, and a connecting rod system. It converts the rotational motion of the motor into the up and down reciprocating motion of the compression piston.

Compression cylinder and working cylinder. The upper and lower parts of the compression cylinder and the working cylinder are connected to the upper and lower rotary valves. The compressed air generated by the up and down movement of the compression piston drives the working piston to move up and down.

Drop part. The drop part is composed of the working piston, hammer rod and upper anvil. The hammer rod and the working piston are a whole. In order to make their weight meet the technical specifications, they need to be made into hollow parts. The connection between the hammer rod and the hammer head is connected by dovetail grooves and wedge irons.

Gas distribution mechanism. The gas distribution mechanism is composed of upper valves, lower valves, operating handles or foot levers, etc., and the realization of various actions is controlled by the gas distribution mechanism.

Anvil. The anvil is installed with anvil pads and lower anvil blocks. In order to meet the stability of forging, the mass requirement of the anvil is 12-15 times the mass of the drop part. It is installed on a solid reinforced concrete foundation with pads in between to eliminate the vibration generated by hammering.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.