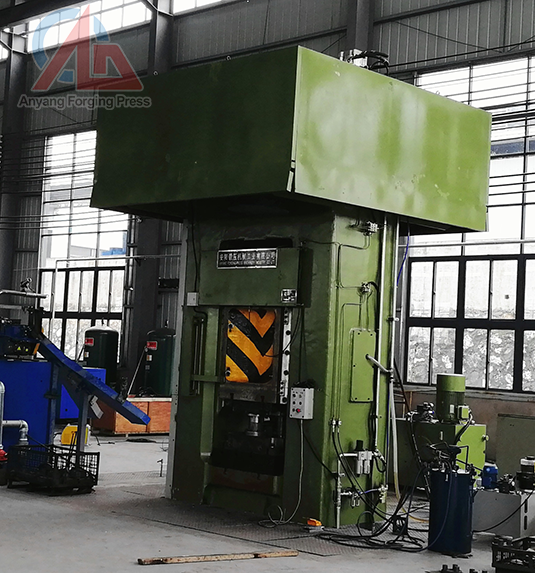

Anyang Forging Electric Screw Press

The electric screw press adopts the gear transmission mode, which is characterized by the use of a special motor with high speed and small torque. The presses of different tonnages use special motors of different powers, which are easy to replace when the motor fails. The maintenance is convenient and simple, and the performance of the motor will not be affected by the wear of the screw guide sleeve.

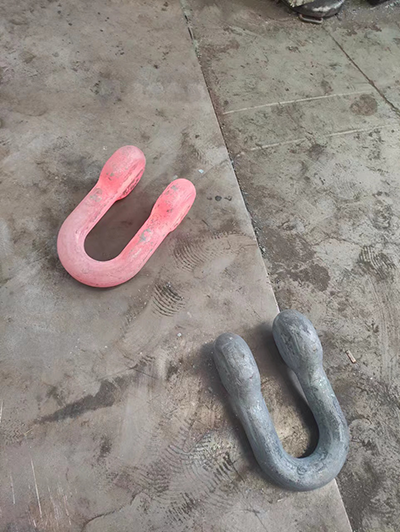

Electric screw press is a kind of forging equipment with strong technological applicability, taking into account the dual properties of forging hammer and press, and has the characteristics of simple structure, small size, short transmission chain, convenient operation, safe operation and small maintenance workload. It is suitable for various processes such as precision forging, finishing, precision pressing, embossing, correction, and leveling. The striking energy can be set accurately, the stroke is short, and the energy is stable. The striking energy can be adjusted according to the molding needs, reducing the mechanical stress and thermal stress of the mold, and prolonging the life of the mold. Because of its low slider speed, it has unique advantages in forging non-ferrous metals such as aluminum alloy and copper.

Working principle of electric screw press

The motor drives the slider to move up and down through the pinion gear, the large gear and the screw. The large gear has enough inertia and plays the role of energy storage of the flywheel. After the start signal is input, the motor drives the slide block to accelerate down through the pinion gear and the big gear from a static state. When the motor reaches the speed required by the preset striking energy, the motor stops accelerating, and the kinetic energy stored by the large gear works to make the part shape. . At the same time, the motor immediately drives the large gear to reverse, and after returning to a certain angle, the motor enters the braking state, so that the large gear drives the slider back to the preset position. Since the sliding block is braked by the motor during the return stroke, the mechanical brake only works when the sliding block is close to the top dead center, and the braking material is not easy to wear and does not need to be replaced frequently.

If you are interested in it, please contact me.

Luca

Luca@anyanghammer.com

WhatsApp/WeChat: +86-16692292860