In the long history of forging technology, blacksmiths have created countless classics with their superb skills and deep understanding of metals. Today, with the advancement of science and technology, the blacksmith hydraulic press, with its powerful power and precise control, perfectly combines traditional forging skills with modern technology, opening up a new revolution in forging.

Features of blacksmith hydraulic press

Powerful power

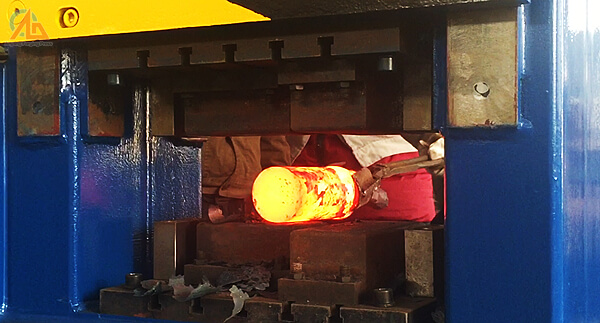

The blacksmith hydraulic press adopts a high-pressure hydraulic system, which can provide strong forging force and easily cope with the forming needs of various metal materials. Whether it is steel, copper alloy or aluminum alloy, the blacksmith hydraulic press can complete the task in the best state.

Precise control

Through the advanced hydraulic control system, the blacksmith hydraulic press can accurately control the forging pressure and speed to ensure that the size and shape of each product meet the design requirements. Its high-precision forging capability provides a solid guarantee for the production of high-quality forgings.

Efficient production

Compared with traditional manual forging, the blacksmith hydraulic press has a high degree of automation, can achieve continuous operation, and greatly improve production efficiency. At the same time, its fast die change function also significantly shortens the production preparation time, winning more market competitiveness for the company.

Energy saving and environmental protection

The blacksmith hydraulic press adopts an efficient hydraulic drive system, which can achieve efficient use of energy and reduce energy consumption. In addition, its low noise and low vibration characteristics also provide better environmental protection for the working environment.

Strong flexibility

Through simple adjustments, the blacksmith hydraulic press can easily adapt to the forging needs of different shapes and specifications. Whether it is small batch customization or large-scale production, the blacksmith hydraulic press can complete the task in the best state.

Application field of blacksmith hydraulic press

Traditional handicrafts

In the manufacture of traditional handicrafts, the blacksmith hydraulic press can produce a variety of exquisite handmade knives, iron art decorations, etc. in an efficient and precise manner, which not only retains the essence of traditional craftsmanship, but also greatly improves production efficiency.

Hardware tools

Blacksmith hydraulic presses are widely used in the production of hardware tools such as hammers, wrenches, pliers, etc. Its efficient and continuous production characteristics can meet the market demand for large quantities and high-quality tools.

Mechanical parts

In the field of mechanical manufacturing, blacksmith hydraulic presses are used to produce various shaft parts, gears, connectors, etc. Its high precision and high efficiency provide strong support for the manufacturing of mechanical equipment.

Auto parts

Blacksmith hydraulic presses are also widely used in the manufacture of auto parts, used to produce engine parts, transmission system parts, etc. Its stability and high efficiency meet the high standards of automobile manufacturing.

Building hardware

In the manufacture of building hardware, blacksmith hydraulic presses are used to produce door hinges, locks, brackets, etc. Its strong power and precise control ensure the durability and reliability of the products.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.