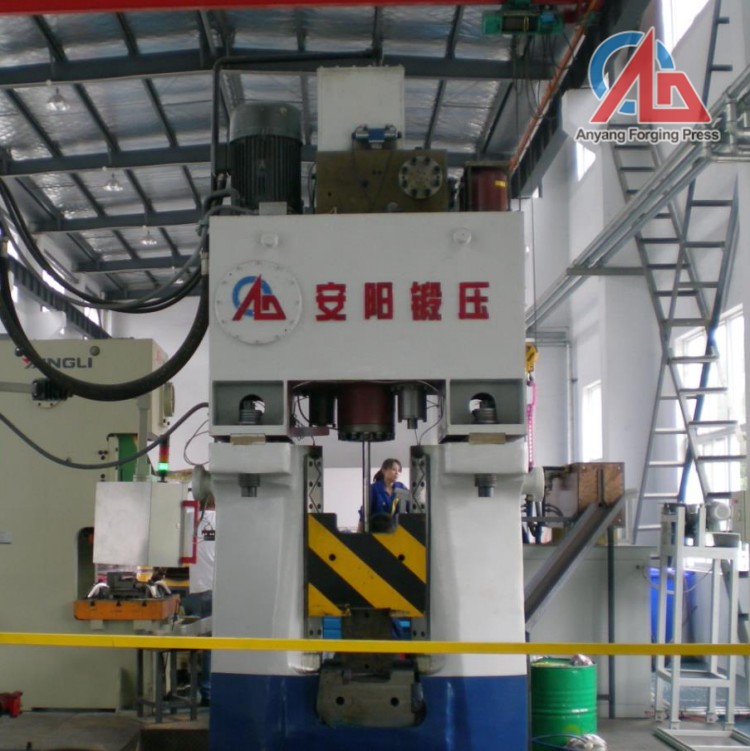

Advantages of Hydraulic Closed Die Forging CNC Hammer Automated Production Line

Advantages of Hydraulic Closed Die Forging CNC Hammer Automated Production Line are mainly reflected in the following aspects:

Precise control: Through the CNC system, the impact force, frequency and stroke of the hammer can be accurately controlled to ensure the consistency of the size and shape of the forged product, and improve the precision and quality of the product.

High efficiency: The CNC hammer works fast and can perform high-frequency forging operations, significantly improving production efficiency and achieving mass production.

Real-time monitoring and feedback: The automated system is usually equipped with a real-time monitoring function, which can obtain production data in a timely manner, monitor the operating status of the equipment, and facilitate timely adjustment and maintenance.

Flexibility: The CNC hammer can be quickly adjusted according to different production needs, adapt to a variety of processes and product specifications, and flexibly respond to market changes.

Reducing product defect rate: Through precise control and monitoring, problems can be discovered and corrected in time during the production process, reducing product defects and improving the pass rate.

Cost savings: The automated production line reduces manual operations, reduces labor costs, and improves production efficiency, thereby reducing the production cost per unit product.

Automated production line integration: CNC hammers can be integrated with other equipment (such as feeding systems, material retrieving systems, etc.) to achieve a fully automated production process, reduce manual intervention, and improve overall production efficiency.

In summary, the CNC hammer automated production line has significant advantages in improving production efficiency, reducing costs, ensuring product quality and enhancing safety, and is an important development trend in the modern forging industry.

Felicia

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870.

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.