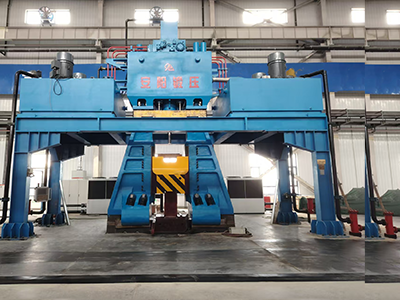

Advantages of CNC Fully Hydraulic Closed Die Forging Hammer forged track links

Track link forging is a key process for manufacturing track links (used in rail transportation, heavy machinery, etc.). Forging technology is usually used to improve its strength, toughness and wear resistance.

The core advantages of hydraulic die forging CNC hammer forging track links include the following aspects:

High-precision processing: CNC technology can achieve high-precision forging process, ensuring that the size and tolerance of the track link are controlled within the optimal range, thereby improving the overall quality of the product.

Strong flexibility: CNC hammer can quickly adjust processing parameters, so that the same equipment can complete the manufacture of track links of different specifications and shapes, and improve production flexibility.

High degree of automation: CNC system can achieve fully automated operation, reduce manual intervention, reduce human errors, and improve production efficiency.

High production efficiency: Compared with traditional forging process, CNC hammer forging can shorten the production cycle, increase output, and improve overall production efficiency.

Optimized material utilization: CNC hammer forging can reasonably design forging path and process, reduce material waste, and improve material utilization.

Improved process conditions: CNC hammer helps to better control the plastic deformation process and provide better process conditions for the forging of track links.

Felicia

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.