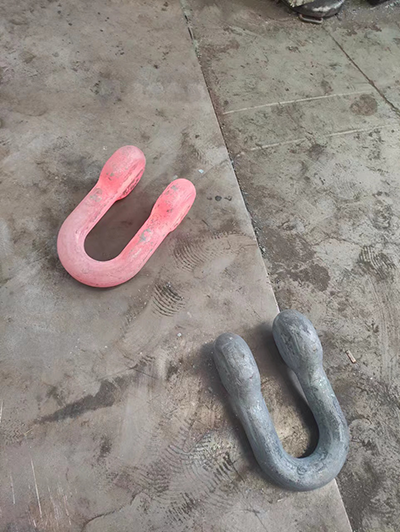

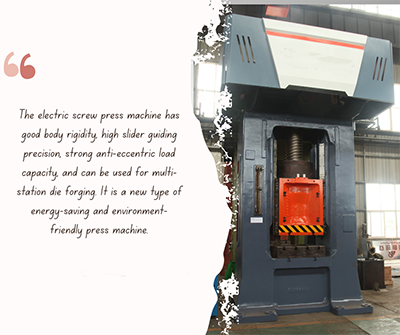

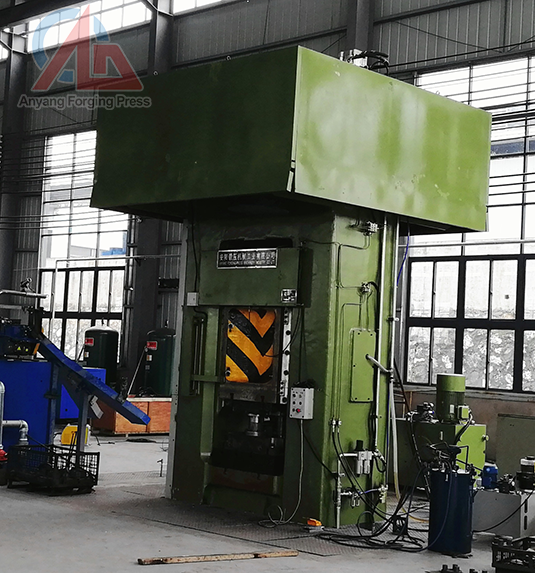

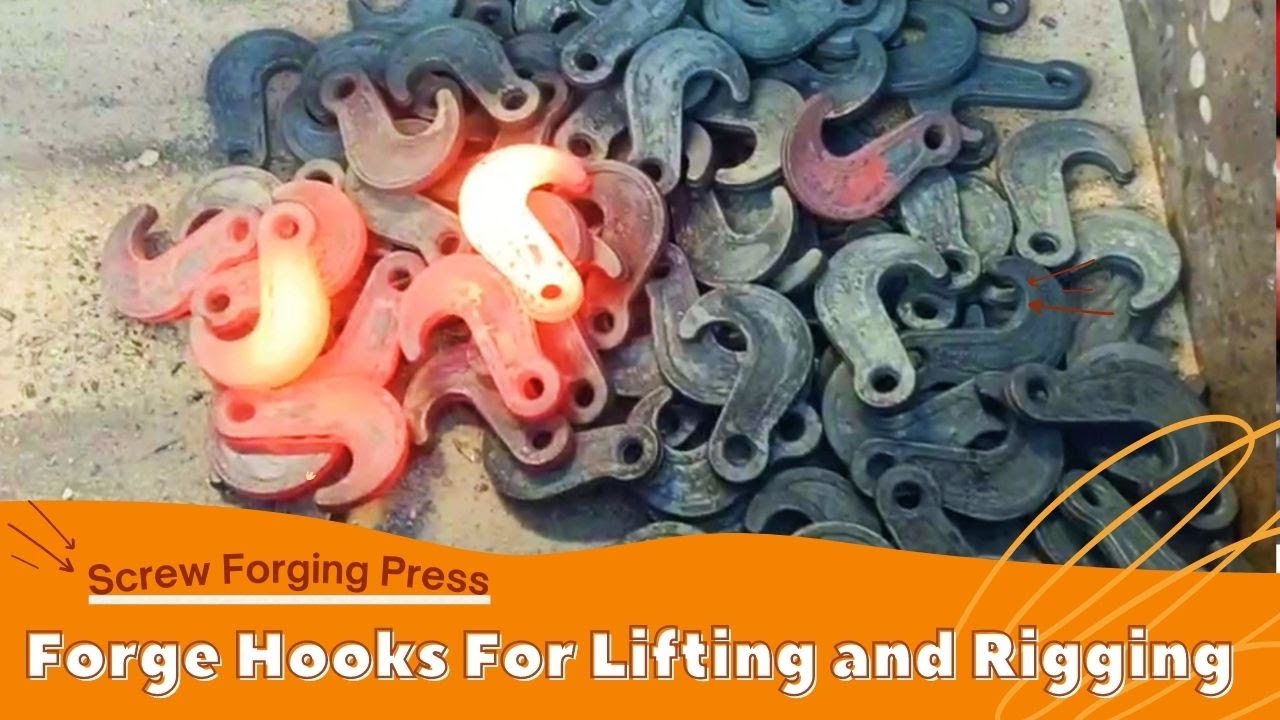

Electric screw press plays an important role in forging hardware rigging. Through advanced technology and reliable performance, it can effectively improve production efficiency and product quality. For companies that want to produce high-quality hardware rigging, choosing a suitable electric screw press will be a wise choice.

Advantages of electric screw press for forging hardware rigging

High-precision forming:

The electric screw press can accurately control the pressure and stroke, so that the hardware rigging can maintain high-precision shape and size during the forging process, which helps to improve the consistency and quality of the product.

Efficient production:

The rapid start and stop capability of the equipment greatly improves production efficiency, which can meet the needs of large-scale production and shorten the production cycle.

Easy operation:

The electric control system makes operation easier and easy to maintain, which helps operators to quickly get started and operate.

Energy saving and environmental protection:

Compared with traditional hydraulic presses, electric screw presses are more energy-saving and reduce the impact on the environment.

Versatility:

The equipment parameters and dies can be adjusted according to the needs of different types of hardware rigging, and can adapt to the forging processing of various block, strip and tubular products.

During your use, if you have any questions or needs, please feel free to contact our after-sales service team, we will wholeheartedly provide you with support and help.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.